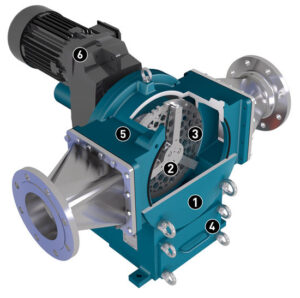

Rotary Lobe Pumps

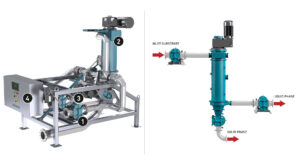

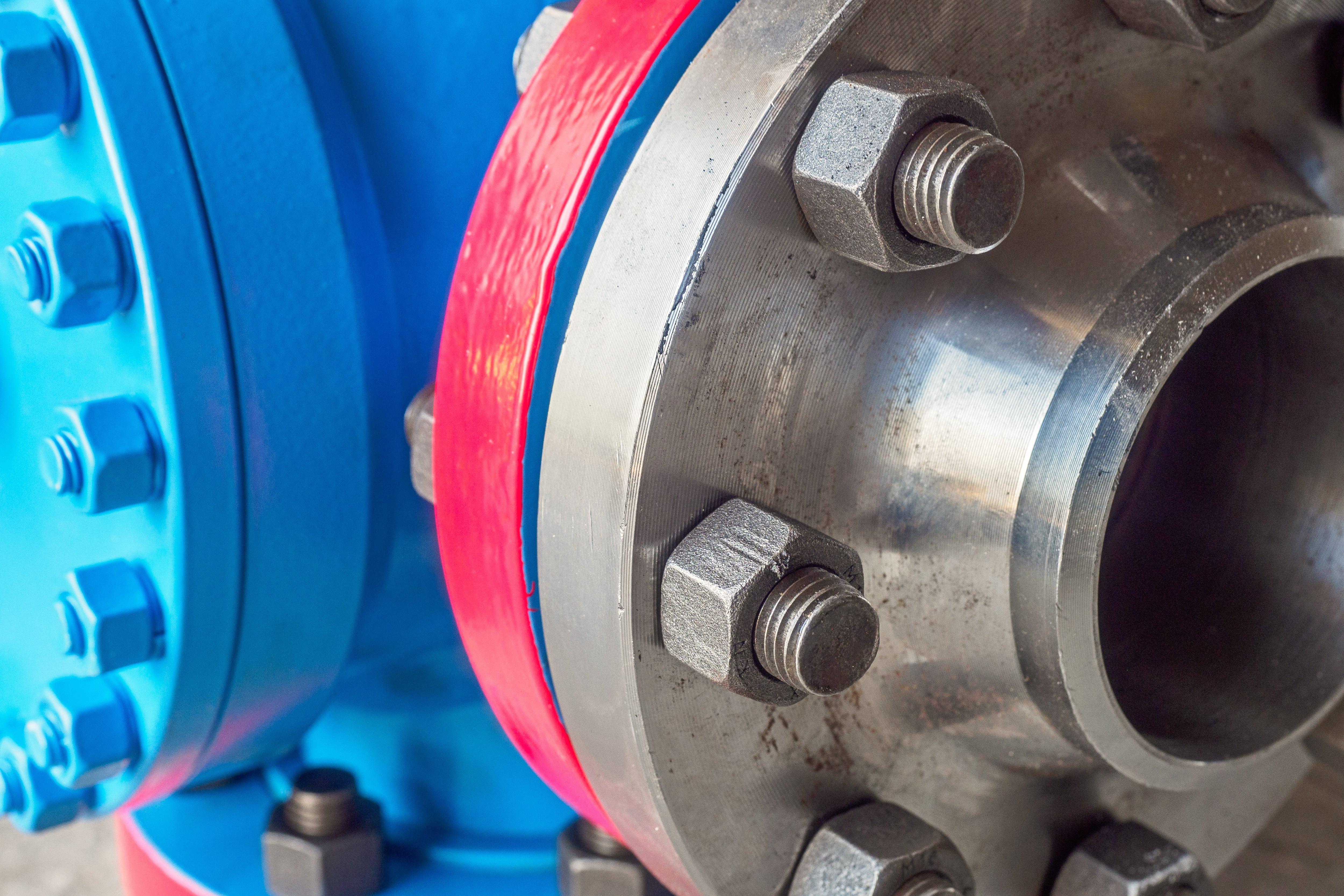

We specialize in various industries designed for efficient, hygienic, and reliable fluid transfer in high-demonstration rotary lobe pumps. Engineers for accuracy and durability, our pumps handle a wide range of viscosities, making them ideal for food processing, pharmaceuticals, chemicals, and wastewater treatment. With innovation and quality attention, our rotary lobe pumps ensure smooth operation, gentle product handling, and compliance with industry standards. Designed for easy maintenance and spontaneous integration, Amed pumps optimize workflows while maintaining costs and safety. Whether in the demand for industrial environments or sanitary applications, our solutions provide coherent, controlled, and efficient fluid transfer.

Rotary Lobe Pumps Manufacturers

Rotary lobe pumps are important for skilled and hygienic fluid switching and are broadly used in industries such as food and drinks, pharmaceuticals, chemical compounds, and waste treatment. These pumps offer a clean, low shear pumping movement, making them ideal for managing touchy or sticky substances. Many primary manufacturers produce exquisite rotary lobe pumps, recognized for their reliability, accuracy, and durability.

Viking Lobe Pump

Viking Pump is a well-established manufacturer specializing in rotary lobe pumps for industrial applications, including food, drinks, and chemical processing. Their pumps are engineered for high efficiency, offering smooth fluid transfer while reducing toil and beating. With strong construction and easy maintenance features, Viking lobe pumps ensure long-lasting performance and compliance with strict sanitary standards.

Q-Pumps

Q-Pumps is a worldwide leader in hygiene industrial rotary lobe pump services designed for the food, dairy, pharmaceutical, and cosmetic industries. Their pumps are designed with stainless steel additives to ensure infection-free transfer, which makes them ideal for applications requiring strict hygiene. Q-pumps prioritize efficiency and ease of cleanliness, providing compatibility for CIP (Clean-in-Place) and SIP (Sterilize-in-Place) seamless operations.

Netzsch

Netzsch rotary lobe pump produces advanced rotary lobe pumps that excel in dealing with notably viscous, abrasive, and shear-sensitive fluids. Their designs are tailored to electricity efficiency and sturdiness, chemical processing, wastewater treatment, and provider to industries such as oil and gas. Netzsch pumps are regarded for their revolutionary rotor generation, ensuring reliable, low-maintenance operation even in traumatic environments.

Borger

Borger is a major manufacturer of lobe pumps designed for industrial and municipal applications. Their pumps are highly versatile and capable of transferring thick mud, chemicals, and food products with accuracy. Borgar emphasizes durability and serviceability, offering a modular design for easily replaceable wearing parts and quick maintenance, giving them a cost-effective solution for long-term use.

Choose Rotary Lobe Pumps at AMED-US

High-pressure rotary lobe pumps play an important role in accurate, clean, and efficient fluid transfer in industries such as food and drinks, pharmaceuticals, chemicals, and wastewater management. When selecting the right pump, reliability and performance are necessary – a direct tool increases workflow efficiency, reduces downtime, and ensures accurate liquid handling for your processes.

At AMED-US, we understand that every industry has unique requirements, which is why we offer customized rotary lobe pump solutions tailored to your needs. Our rotary lobe pump parts are designed with safety, durability, and sustainability in mind, incorporating the latest energy-efficient technology to reduce waste and optimize performance. Whether you need chemical-resistant materials, hygienic designs, or heavy-duty industrial pumps, our solutions meet the highest industry standards while ensuring safe and eco-friendly operations.

Get in Touch – Request a Quote or Consultation Today

Looking for the best rotary lobe pump for your application? Contact our experts to discuss your needs, explore our high-performance solutions, or request a quote. We are here to help you find the most reliable, efficient, and cost-effective pump for your business!

Frequently Asked Questions

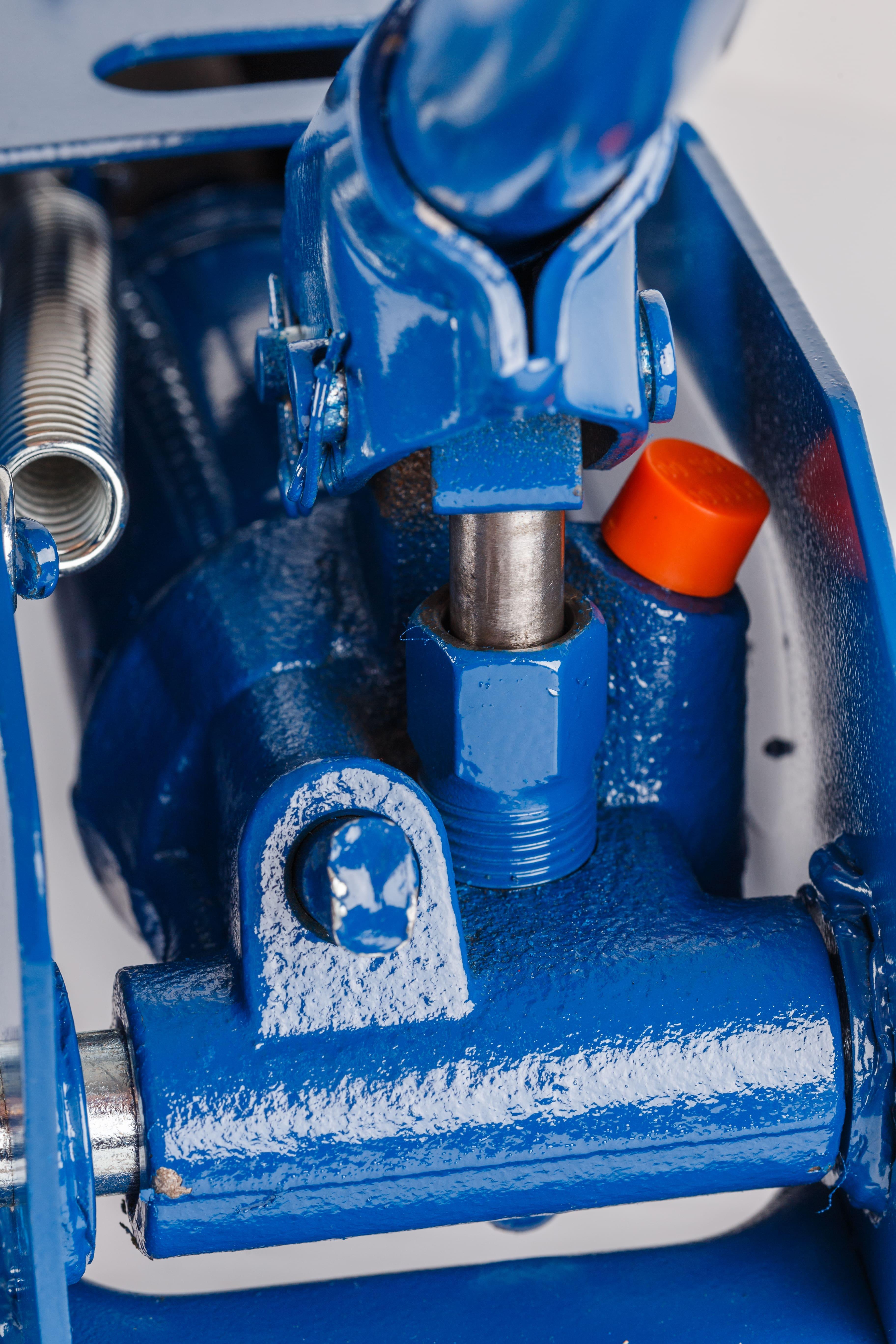

A rotary lobe pump is a wonderful displacement pump designed for the soft and green transfer of fluids, inclusive of distinctly sticky and shear-sensitive substances. It has a rotating lobe that transfers fluids through the pump chamber without direct touch, ensuring hygiene and contamination-free operation. These pumps are widely used because of their durability, reliability, and capacity to handle solid and delicate fluids in the food, remedy, chemical, and wastewater industries.

Rotary lobe pump applications operate by using two synchronized rotating lobes that form cavities, drawing fluids internally and may be easily displaced. Non-touch lobes ensure low shear pressure, making them best for delicate merchandise such as dairy, sauces, and prescribed drugs. Their consistent and skilled wafers make them a favorite option for industries requiring correct fluid handling.

Rotary lobe pumps are not designed for extended dry running, as it may cause excessive heat buildup and seals and components possible damage. However, some models come with special seal systems or external lubrication to handle brief dry-hanging conditions. It is always recommended to ensure proper priming and fluid appearance to maintain optimal performance and longevity.

Rotary lobe pumps provide versatility, efficiency, and clean operations, making them ideal for industries that require accurate and contamination-free fluid transfer. They can handle sticky, abrasive, and shear-sensitive materials without compromising quality, including food products, chemicals, and slurries. Additionally, their low maintenance design and easy cleaning options, such as CIP (clean-in-place) systems, make them a cost-effective and reliable option.

Yes, at AMED-US, we offer complete after-income help, including setup, steerage, troubleshooting, and maintenance help. Our group of specialists is available to help you optimize the pump’s overall performance and cope with any technical concerns. We also provide spare elements, servicing, and long-term maintenance plans to make sure your pump operates efficiently for years.

Rotary lobe pumps require regular inspection and lubrication to ensure clean operation and longevity. Routine preservation includes checking seals, gaskets, and bearings for wear, cleansing the pump chamber, and replacing parts when necessary. With proper care and periodic servicing, these pumps can supply years of reliable and green performance in demanding industrial applications.