Flex-A-Seal Flushless Slurry Pump Seal

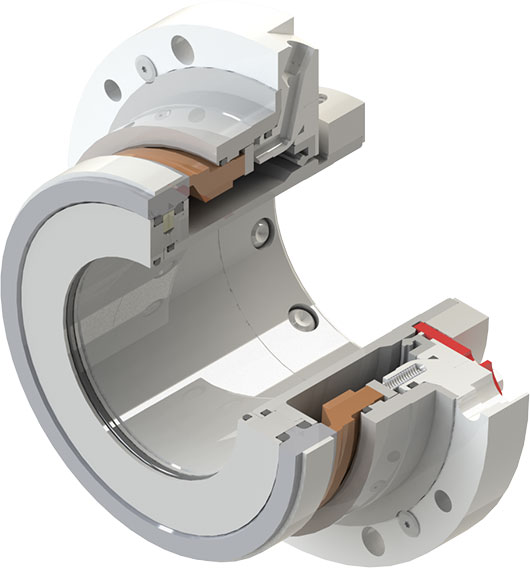

Introducing the Flex-A-Seal Flushless Slurry Pump Seal, a revolutionary solution for preventing leaks and extending the life of slurry pumps. This innovative seal eliminates the need for flush water, reducing maintenance costs and increasing pump efficiency.

Brand: Flex-A-Seal Manufacturer

MPN:

- Description

- Reviews

- Documentation

General Information

The Flex-A-Seal Flushless Slurry Pump Seal is a highly durable and efficient sealing solution designed for use in pump systems handling corrosive slurries. This seal is specifically engineered to eliminate the need for external flush water, making it ideal for applications where water conservation is a priority.

1. Superior durability: The Flex-A-Seal Flushless Slurry Pump Seal is constructed from high-quality materials that ensure long-lasting performance and reliability in demanding industrial environments.

2. Environmentally friendly: By eliminating the need for external flush water, this seal helps reduce water usage and minimize environmental impact, making it a sustainable choice for pump systems.

3. Easy installation and maintenance: This seal is designed for quick and simple installation, and its robust construction requires minimal maintenance, reducing downtime and operational costs.

4. Versatile application: The Flex-A-Seal Flushless Slurry Pump Seal is suitable for a wide range of industries and pump systems handling abrasive and corrosive slurries, offering versatility and flexibility in various applications.

Why choose Flex-A-Seal Flushless Slurry Pump Seal?

The Flex-A-Seal Flushless Slurry Pump Seal is an excellent choice for sealing applications where traditional seals are not effective due to high solids content. This innovative design eliminates the need for flush water, reducing maintenance costs and downtime. With its robust construction and reliable performance, the Flex-A-Seal Flushless Slurry Pump Seal is the ideal solution for demanding slurry pumping applications.

Overview of Flex-A-Seal Flushless Slurry Pump Seal

The Flex-A-Seal Flushless Slurry Pump Seal is designed to provide a reliable sealing solution for slurry pump applications. This innovative seal eliminates the need for flushing water, which helps reduce water consumption and maintenance costs.

Key features of the Flex-A-Seal Flushless Slurry Pump Seal include a robust design that can withstand the harsh conditions typically found in slurry pump applications. The seal is also designed to be easy to install, saving time and resources during the maintenance process.

With its ability to operate without the need for flushing water, the Flex-A-Seal Flushless Slurry Pump Seal is ideal for applications where water conservation and cost efficiency are priorities. This seal is designed to provide long-lasting performance and reliability, helping to minimize downtime and ensure the smooth operation of slurry pumps.

Overall, the Flex-A-Seal Flushless Slurry Pump Seal is a superior sealing solution for slurry pump applications, offering efficiency, reliability, and cost savings.

Technical specifications of Flex-A-Seal Flushless Slurry Pump Seal

Currently in stock

Currently in stock

Heed help?

Get in touch with our team