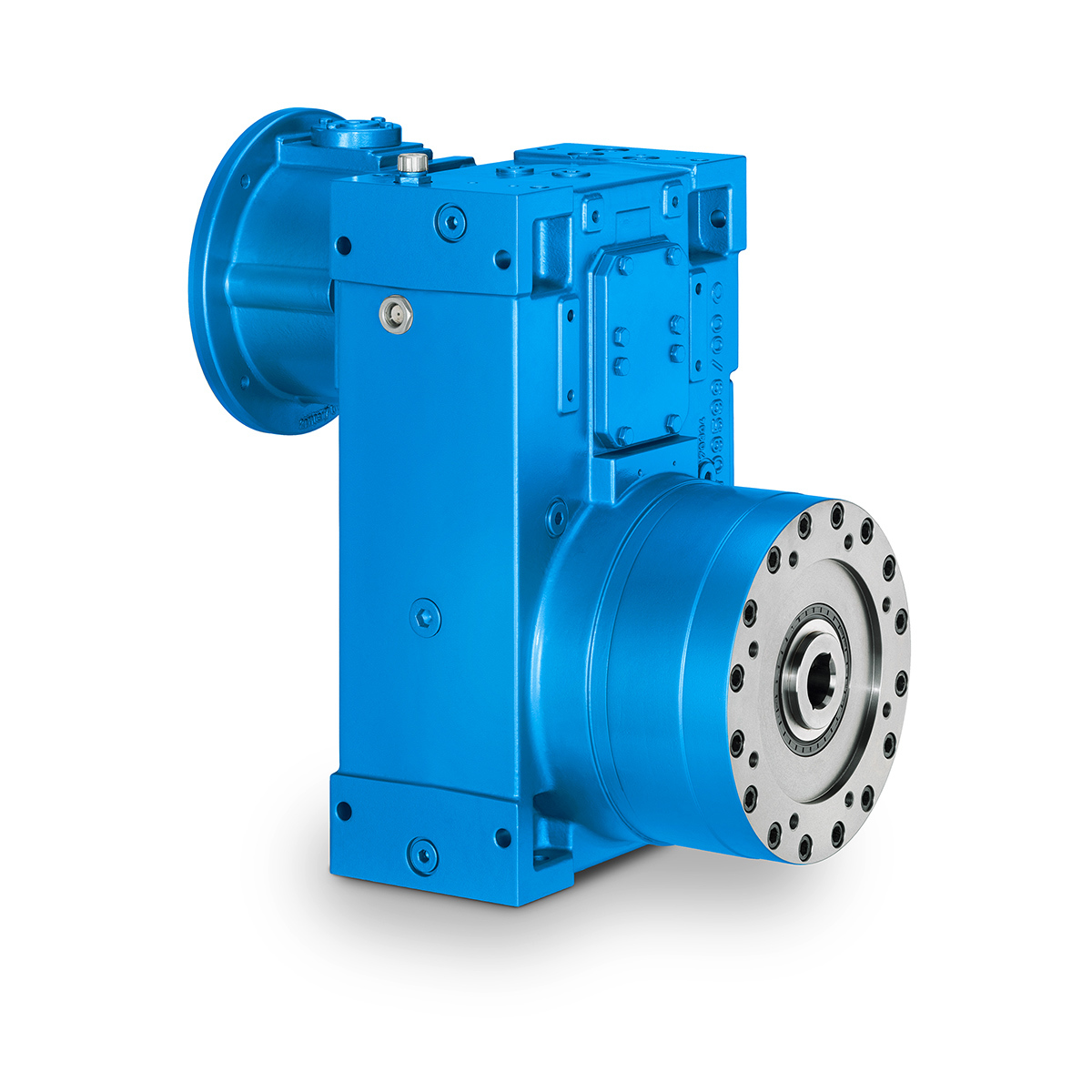

Flender Single Screw Extruders Gear Units

Flender Single Screw Extruders Gear Units are specially designed for the demanding requirements of the Chemicals, Oil and Gas industry. With precision engineering and high-quality materials, these gear units ensure efficient mixing and processing of various substances with ease and reliability.

Brand: Flender Manufacturer

MPN:

- Description

- Reviews

- Documentation

General Information

Flender Single Screw Extruders Gear Units are essential components in the mixing process for chemicals, oil, and gas applications. These high-quality gear units are specifically designed for single screw extruders, providing reliable and efficient performance for various industries.

1. Precision Engineering: Flender Single Screw Extruders Gear Units are engineered with precision to ensure optimal mixing and extrusion of chemicals, oil, and gas materials.

2. Durable Construction: These gear units are built to withstand heavy-duty use in demanding industrial environments, ensuring long-lasting performance and reliability.

3. Efficient Power Transmission: With high torque capacity and efficient power transmission, Flender gear units maximize productivity and minimize downtime in mixing operations.

4. Wide Range of Applications: Suitable for a variety of chemicals, oil, and gas applications, Flender Single Screw Extruders Gear Units are versatile solutions for various industrial processes.

Why choose Flender Single Screw Extruders Gear Units?

The Flender Single Screw Extruders Gear Units are a top choice for the chemicals, oil, and gas industry due to their exceptional reliability, durability, and efficiency. These gear units deliver precise torque and speed control, ensuring consistent performance and high productivity. With their compact design and easy maintenance, Flender gear units are ideal for demanding applications in the chemicals, oil, and gas sector.

Overview of Flender Single Screw Extruders Gear Units

Flender Single Screw Extruders Gear Units are a versatile and efficient solution for the mixing of chemicals in the oil and gas industry. These gear units are designed to provide high torque and low speed, making them ideal for demanding mixing applications.

Key points and features of the Flender Single Screw Extruders Gear Units include:

– High torque capacity: These gear units are capable of handling high torque requirements, ensuring efficient mixing of chemicals.

– Low speed: The gear units operate at low speeds, providing precise and controlled mixing for chemical processes.

– Robust design: The gear units are built to withstand the harsh conditions found in the oil and gas industry, ensuring reliable operation.

– Easy maintenance: With a simple design and easy access to components, maintenance is quick and hassle-free.

– Customizable options: Flender offers a range of options for the Single Screw Extruders Gear Units, allowing for customization to meet specific application requirements.

Overall, the Flender Single Screw Extruders Gear Units are a reliable and efficient solution for mixing chemicals in the oil and gas industry, providing high torque capacity, low speed operation, and easy maintenance.

Technical specifications of Flender Single Screw Extruders Gear Units

Currently in stock

Currently in stock

Heed help?

Get in touch with our team