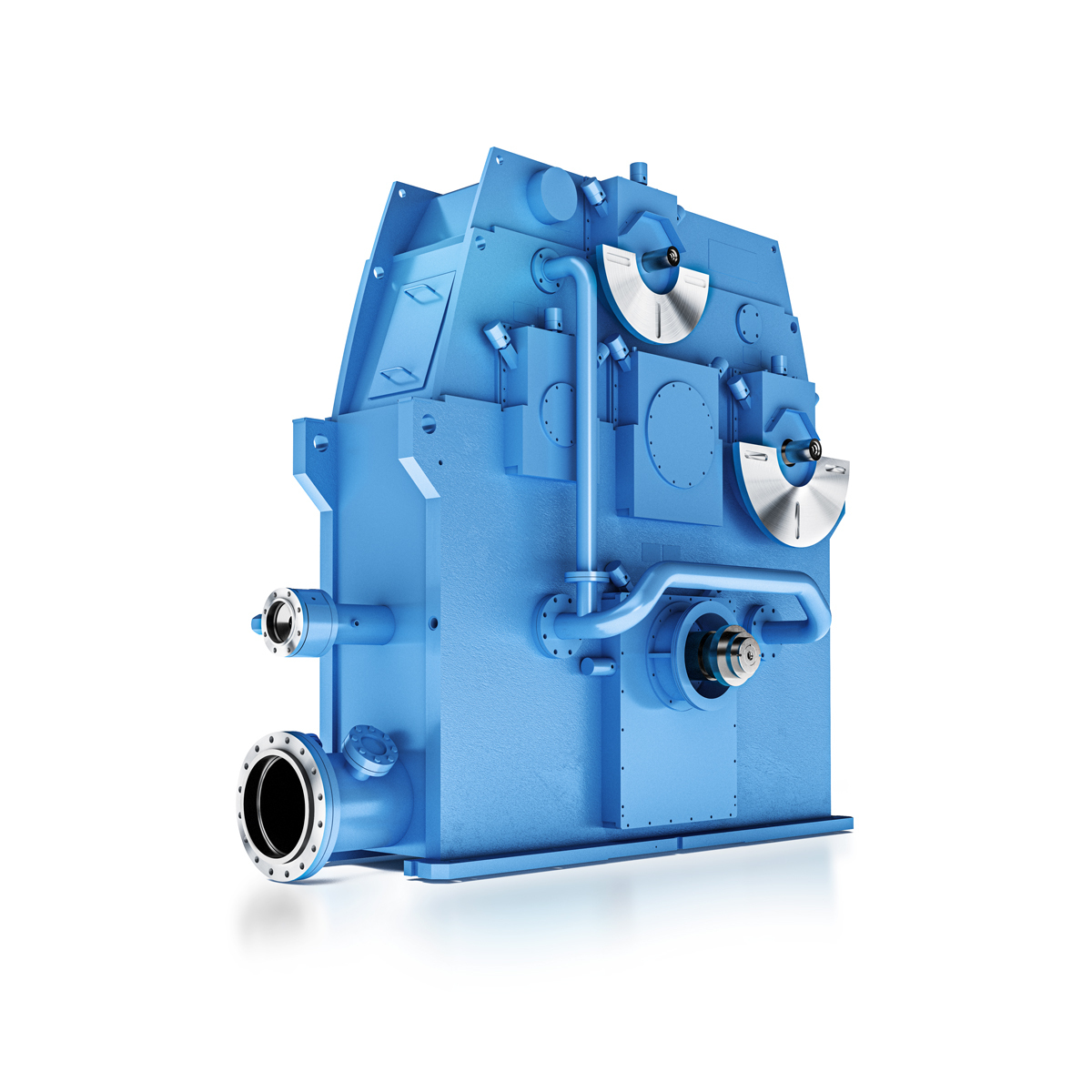

Flender Integral Gear Units

Flender Integral Gear Units for mixers in the Chemicals, Oil and Gas industry offer reliable and high-performance solutions for blending and mixing processes. Designed for efficiency and durability, these gear units ensure smooth operation and optimum performance in demanding applications.

Brand: Flender Manufacturer

MPN:

- Description

- Reviews

- Documentation

General Information

The Flender Integral Gear Units are high-performance gearboxes specifically designed for mixers used in the chemicals, oil, and gas industries. These gear units are known for their reliability, efficiency, and durability in demanding industrial applications.

1. Robust Design: The Flender Integral Gear Units feature a sturdy construction with high-quality materials, providing maximum torque capacity and longevity in harsh operating conditions.

2. Smooth Operation: With optimized gear geometry and precise manufacturing, these gear units ensure smooth and efficient operation, minimizing vibrations and noise during mixing processes.

3. Versatile Applications: The Flender Integral Gear Units are suitable for a wide range of mixer applications, including blending, emulsifying, and homogenizing in the chemicals, oil, and gas industries.

4. Easy Maintenance: These gear units are designed for easy installation and maintenance, reducing downtime and overall operating costs for industrial facilities.

Why choose Flender Integral Gear Units?

The Flender Integral Gear Units are a top choice for mixers in the chemicals, oil, and gas industries due to their high reliability and efficiency. These gear units are designed to withstand harsh operating conditions, ensuring continuous operation without any downtime. With their compact design and easy maintenance, they provide a cost-effective solution for mixing applications in these demanding industries.

Overview of Flender Integral Gear Units

Flender Integral Gear Units are high-performance gear units specifically designed for mixers in the chemicals, oil, and gas industry. These gear units are known for their reliability, durability, and efficiency, making them a top choice for handling the demanding requirements of mixing applications in these industries.

Key points and features of the Flender Integral Gear Units include:

1. Compact design: The gear units are designed to be compact, saving space in industrial settings.

2. High efficiency: These gear units are highly efficient, ensuring smooth and reliable operation during mixing processes.

3. Robust construction: Flender Integral Gear Units are built to withstand the harsh conditions of the chemicals, oil, and gas industry, ensuring long-lasting performance.

4. Easy maintenance: These gear units are designed for easy maintenance, reducing downtime and maximizing productivity.

Overall, Flender Integral Gear Units are an excellent choice for mixers in the chemicals, oil, and gas industry, offering superior performance, reliability, and efficiency for demanding mixing applications.

Technical specifications of Flender Integral Gear Units

Currently in stock

Currently in stock

Heed help?

Get in touch with our team