Ever wondered why your basement bathroom works perfectly despite being below street level? The answer likely involves a hidden mechanical hero working behind the scenes. Pumping stations solve one of plumbing’s biggest challenges: переміщення відходів в гору when gravity simply won’t cooperate. These systems kick into action wherever natural drainage hits a dead end.

Key Takeaways

- You need a pump station when gravity fails. Basement bathrooms, low-lying properties, or anywhere sewage needs to travel uphill — that’s when these systems earn their keep.

- Size matters, but bigger isn’t always better. Most homeowners need a simple single-pump setup. Duplex systems make sense for multiple units or commercial properties. Municipal-scale installations are overkill unless you’re building shopping centers.

- Maintenance determines everything. Annual service costs a few hundred dollars for residential systems. Skip it and face $15,000+ repair bills when pumps burn out or sewage backs up into your basement.

- Installation isn’t a DIY project. Pump sizing calculations, electrical permits, and code compliance trip up even experienced contractors. Insurance companies won’t cover damage from improper installations.

- Plan for power outages. No electricity means no pumping — toilets and drains stop working until power returns. Backup generators solve this, but add serious cost to any project.

What Is a Pump Station Used for?

Let’s consider the situation: you’re renovating your basement into a rental unit, complete with bathroom and kitchenette. Everything’s going smoothly until your contractor delivers the bad news — your basement floor sits three feet below the main sewer line. Gravity can’t push waste uphill, which means you need a different solution.

So, a pump station forces sewage and wastewater upward when gravity alone can’t do the job. It provides the mechanical boost needed to move waste to higher sewer lines or treatment facilities.

Property owners encounter this challenge more often than you might expect. New subdivisions built in low-lying areas, commercial buildings with below-grade facilities, and older homes with basement additions all face the same physics problem. Water flows downhill naturally, but getting it to flow uphill requires mechanical assistance.

The economics often make pumping stations the smart choice. Digging trenches deep enough for gravity-fed systems can cost tens of thousands of dollars, especially when you hit bedrock or encounter utility lines. A pumping station typically costs far less than massive excavation projects.

Underground vs Above-Ground: Two Schools of Thought

Walk around any neighborhood and you’ll notice something interesting — some pumping stations hide completely underground while others feature above-ground components. This difference reflects decades of engineering evolution and changing safety priorities.

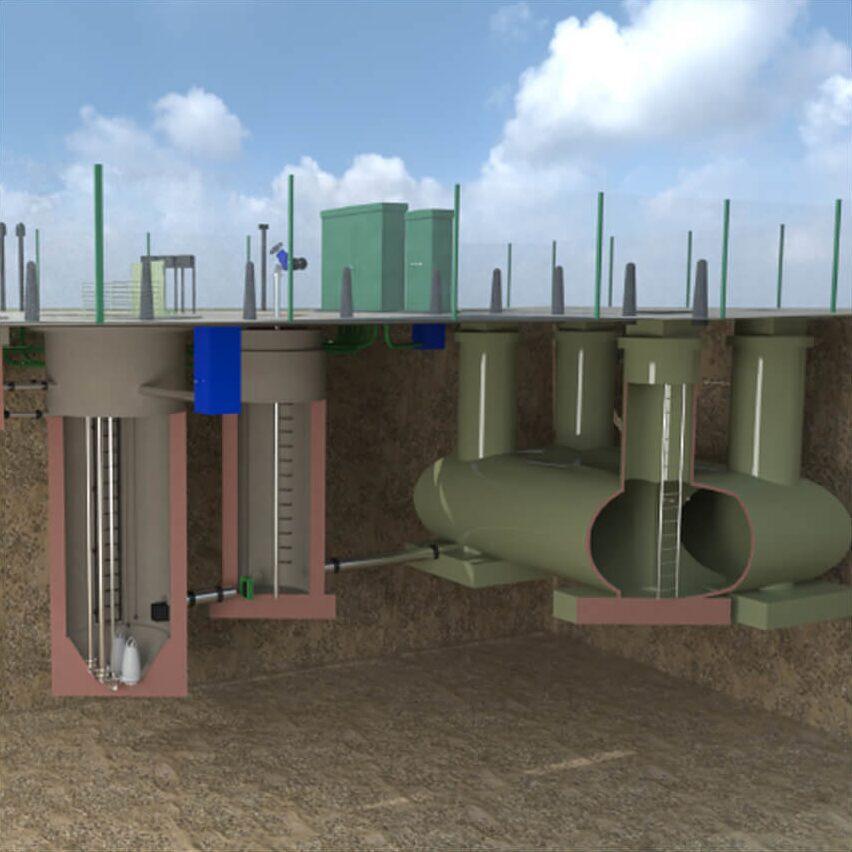

Traditional Underground Systems

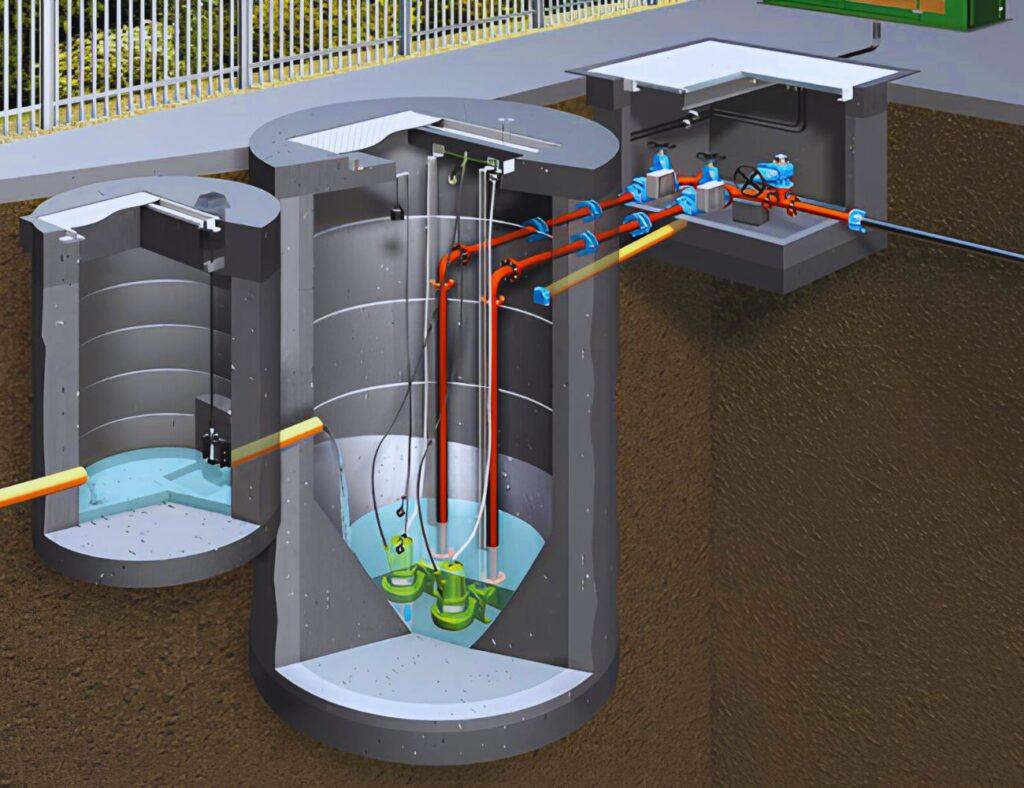

Traditional sewage pumping stations bury everything below ground, creating what engineers call “wet wells” and “dry wells.” The wet well collects incoming sewage, while the dry well houses pumps and electrical equipment. This setup keeps everything out of sight but creates unique challenges.

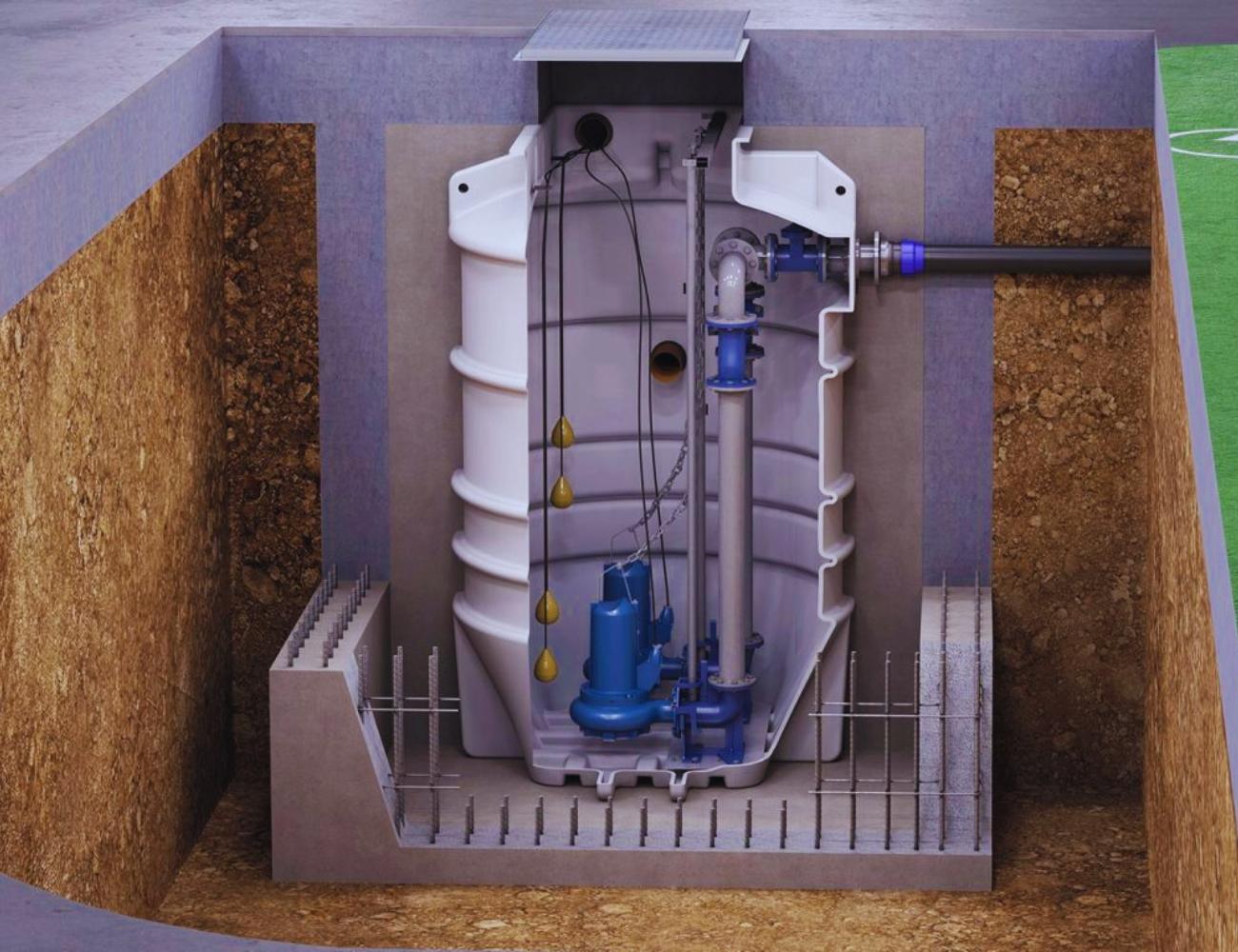

Submersible sewage pumps with closely coupled electric motor are mounted within the wet well itself, submerged within the sewage, representing the newer approach that eliminates dry wells entirely. These submersible systems mount pumps on guide rails with special “duckfoot” connections that allow easy removal for maintenance.

Package pumping stations offer a middle ground — prefabricated units built from materials like polyethylene or fiberglass that arrive ready for installation. These systems reduce installation time but still require underground placement.

Above-Ground Solutions

Here’s where things get interesting from a safety perspective. Above ground pump stations are becoming more popular as they solve the challenges of conventional submersible pumps.

Why the shift? Simple physics and worker safety. Pumps constantly exposed to corrosive sewage break down faster and cost more to maintain. Worse yet, maintenance workers must enter confined underground spaces filled with potentially dangerous gases. Above-ground installations eliminate both problems while making repairs faster and safer.

The Anatomy of a Pumping Station: Parts That Make It Work

Every wastewater pump station contains four essential components that keep the system running smoothly. Knowing these parts helps property owners troubleshoot problems and communicate effectively with service technicians.

The Wet Well

The wet well acts like a temporary storage tank where sewage accumulates before pumping begins. Size matters here — too small and pumps cycle constantly, wearing out faster. Too large and waste sits stagnant, creating odor problems and potential clogs.

Most residential installations use wet wells between 300-1000 gallons, depending on household size and usage patterns. Commercial installations require much larger capacity to handle peak flow periods.

Float Switches

Float switches eliminate manual pump operation. These devices rise and fall with liquid levels, triggering electrical circuits that start and stop pumps automatically.

Here’s how they work: as wastewater enters the wet well, rising liquid levels lift the float switch. When the float reaches a predetermined angle, it closes an electrical circuit that starts the pump. As the pump empties the well, the falling float opens the circuit and stops the pump.

Most installations use multiple float switches — one to start the pump, another to stop it, and a third to trigger high-level alarms if the primary pump fails.

Control Panels

Sewer pump station control panels coordinate everything from pump operation to alarm systems. These units interpret signals from float switches and respond accordingly.

Duplex control panels handle systems with two pumps, automatically alternating between them to ensure equal wear. If one pump fails, the control panel detects the problem and switches to the backup pump while triggering an alarm.

Pumps

Sewage pumps differ significantly from standard water pumps because they must handle solid waste without clogging. Most use open impellers — spinning discs with curved blades that can pass objects up to 3 inches in diameter.

Pump sizing depends on several factors: vertical lift (how high waste must be pumped), horizontal distance to the discharge point, pipe diameter, and expected flow rates. Get the sizing wrong and you’ll face constant problems.

The Operating Cycle From Collection to Discharge

The operational cycle might seem complex, but it follows a surprisingly straightforward sequence. Every time someone flushes a toilet or drains a sink connected to the system, this process kicks into action.

- Stage one begins when wastewater flows into the wet well through incoming pipes. The liquid level slowly rises while the pump remains dormant, waiting for its cue to start working.

- Stage two activates when rising wastewater lifts the “pump on” float switch. This triggers the control panel to start the primary pump, which immediately begins moving liquid through the discharge pipe toward higher ground or the main sewer line.

- Stage three involves the pump running until liquid levels drop enough to lower the “pump off” float switch. The control panel receives this signal and shuts down the pump until the next cycle begins.

Smart installations include backup protocols for heavy usage or system failures. If water levels continue rising despite pump operation, a second “high level” float switch activates backup pumps or triggers alarm systems. This redundancy prevents overflows that could damage property or violate environmental regulations.

The complete journey from your property to the treatment plant might involve multiple pumping stations, each moving wastewater progressively higher until gravity can take over for the final stretch.

Why Pump Station Maintenance Separates Success from Disaster

Pump station failures create serious problems beyond inconvenience — they cause environmental hazards, health risks, and potentially massive cleanup costs. One malfunctioning system can dump raw sewage into basements, yards, or waterways.

The EPA doesn’t mince words about maintenance requirements. They mandate weekly inspections for active pumping stations, recognizing that small problems quickly become big disasters without attention.

The Weekly Walk-Around

Professional maintenance starts with consistent weekly inspections. During these visits, technicians check for obvious problems: unusual noises from pumps, visible leaks around connections, debris accumulation in accessible areas, and proper operation of alarm systems.

These quick checks catch problems like:

- Pump motors running hot (indicating bearing problems)

- Float switches stuck in one position

- Control panel warning lights

- Unusual odors suggesting system backups

Quarterly Deep Dives

Every three months, maintenance crews perform comprehensive inspections. They test electrical connections, clean accumulated grease from wet well walls, exercise valves, and verify backup systems work.

Grease buildup causes most common problems. Professional cleaning removes this buildup before it blocks pumps and creates expensive failures.

Annual Overhauls

Once yearly, pumping stations need thorough inspections that may involve removing pumps for detailed examination. Technicians check impeller wear, replace deteriorating seals, test motor windings, and verify safety systems operate correctly.

What Pumping Stations Really Cost

Installation costs vary wildly based on local conditions. A simple residential system runs $8,000-15,000 installed, while commercial installations hit $50,000 or more. Rock excavation or difficult access pushes costs higher.

Annual maintenance typically costs $3,000-5,000 for commercial installations. Residential systems cost less, but skipping maintenance creates repair bills that often exceed the entire annual budget. Emergency repairs cost three to five times more than preventive care.

Most installations need professional contractors due to pump sizing calculations, local permit requirements, and electrical code compliance. Insurance companies often refuse claims for improper DIY installations.

Choosing the Right Size for Your Needs

Most homeowners need what contractors call a “residential” system – basically a single pump that handles one house or maybe a duplex. You’re looking at a wet well around the size of a large hot tub and a pump that moves 20-30 gallons per minute. That’s plenty for a basement bathroom or small apartment addition.

Developers building subdivisions or apartment complexes step up to dual-pump systems. Two pumps mean one can break down without creating a sewage backup emergency. These handle 20-50 homes, depending on usage patterns.

Municipal systems are a different beast entirely – multiple pumps, backup generators, and monitoring systems that alert operators immediately when something goes wrong. Most property owners never deal with these unless they’re developing major commercial projects.

FAQ

How long do pumping stations last?

The pumps wear out first — usually around 8-12 years. Everything else can run decades longer if you stay on top of maintenance. Skip the annual service and you’ll be lucky to get 5 years before something major breaks.

Can I install a pumping station myself?

Pump sizing calculations alone trip up most contractors, let alone homeowners. Add electrical permits, code inspections, and insurance liability issues – the math rarely works out in favor of DIY.

What happens during power outages?

No power means no pumping. Period. You can’t flush toilets or drain sinks until electricity returns. Backup generators solve this, but cost another $5,000-8,000. Most people just wait it out.

How often do pumps break down?

Float switches cause more headaches than actual pump failures. They get stuck, wiring corrodes, or debris jams the mechanism. The pump itself usually outlasts everything around it when maintained properly.

Do pumping stations create noise or odors?

You’ll hear it kick on — sounds like a dishwasher cycling. Underground units stay quieter than above-ground setups. Smell problems happen when wet wells aren’t sealed properly or maintenance gets ignored.