The paper is a part of everyday life, from books and packaging to currency and artwork. Have you ever stopped to consider which paper it is made from and how it is produced? What is the history of paper? Essentially, the paper is produced by the fiber of the plant – mostly wooden pulp – a flexible yet reduced mechanical and chemical process to produce durable materials. Papermaking is a science that includes breakdown of raw materials, the purification of fibers and sheets through pressure and drying.

While traditional paper is taken from trees, new technology has released new sources such as recycled paper, cotton, and even bamboo, which present the business as environmentally friendly. In this article, we will detect the major components of paper, the steps involved in its production, and how various materials affect its texture, power, and use. Whether you are eager about environmentally friendly options or chemistry behind paper construction, this guide will break attractive science behind one of the most widely used materials in the world.

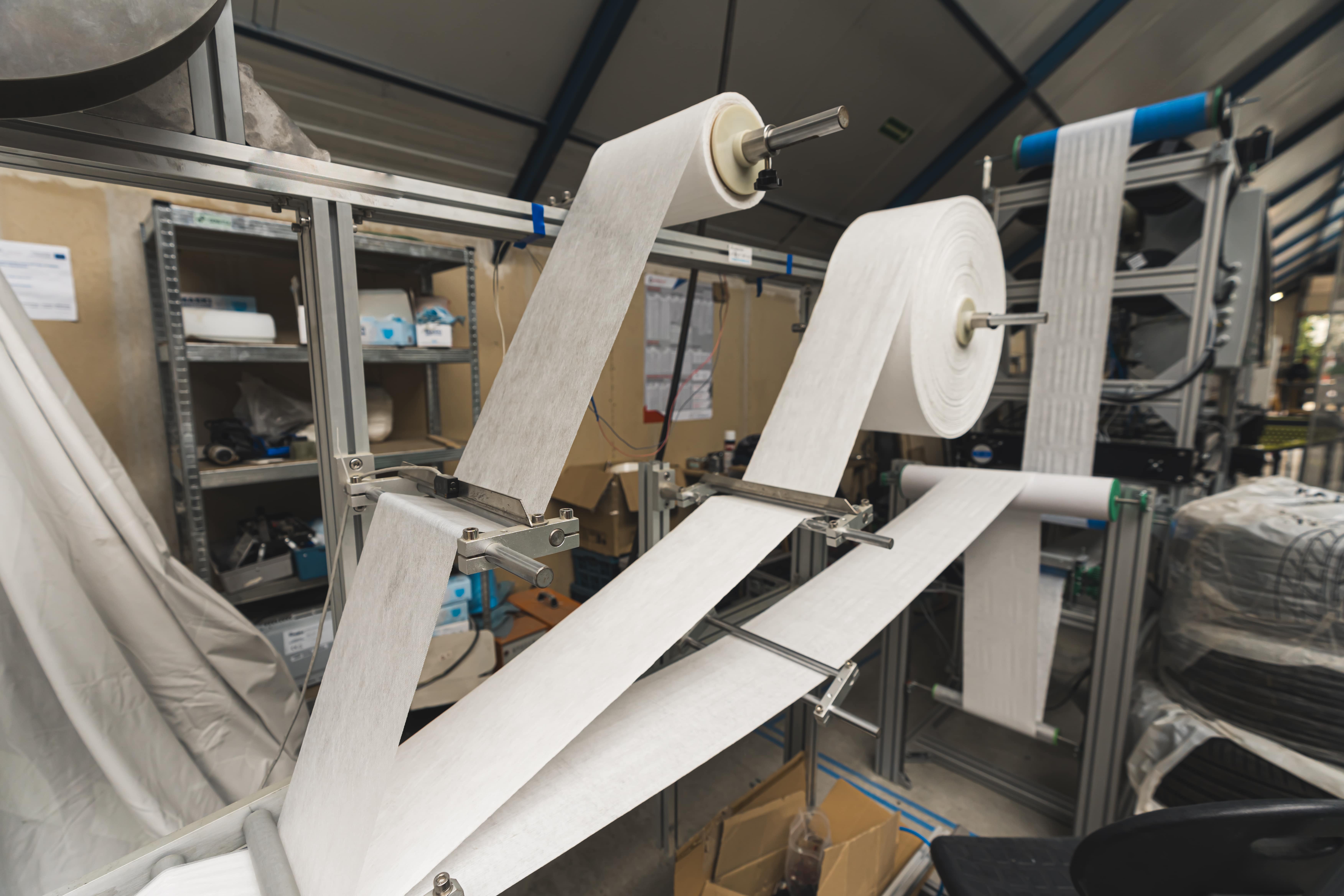

Basics of Paper Manufacturing

The method of converting raw materials such as wood into paper consists of several important steps, each aimed at refining fibers, eliminating impurities, and producing a smooth, strong final product. The core stages of paper production are pulping, pressing, drying, and finishing.

Pulping: Breaking Down Raw Materials

The first stage in the paper production process is pulping, in which plant material (primarily wood) is broken down into a slurry of fibers. The two main forms of pulping are:

- Mechanical pulping: Wood is physically grinded into fibers, keeping more of the original content but producing lower-quality paper.

- Chemical pulping: Sodium hydroxide and sulfates dissolve lignin (wood’s natural glue), producing higher-quality, more robust paper.

Used paper and other fibers such as cotton or bamboo are also pulped, where they are immersed, separated, and washed before being further processed.

Pressing: Creating the Paper Sheet

Once the pulp is purified and filtered, it is cast onto a traveling mesh screen in order to allow excess water to escape. When the fibers settle and become intertangled with one another, they begin forming a thin mat. The wet fibers are forced together by big rollers, which remove even more water and harden them into a thin sheet.

Drying: Consolidating and Harding the Paper

After pressing, the paper is still quite wet. It is passed through a series of hot rollers that gradually evaporate the water. This drying transforms the paper from a weak, soggy condition to a stronger, more durable product, more appropriate for the final stages of production.

Finishing: Refining Quality and Texture

Once dried, the paper may be treated further to enhance its qualities. Finishing processes include:

- Calendering: Running the paper through smooth or textured rollers to achieve a predetermined thickness and surface finish.

- Coating: Applying materials like clay, starch, or polymers to improve smoothness, brightness, or printability.

- Cutting and packaging: The finished sheets are cut to size and packaged for distribution.

Through these processes, raw plant cellulose is transformed into the extensive material globally used for writing, printing, packaging, and numerous other purposes. The technology and material nature at every stage determines the texture, durability, and application of the resulting paper product.

Different Types of Paper

Paper exists in a broad variety of forms that are made for particular purposes based on their composition, thickness, texture, and durability. While all paper is made through the same processes, variations in fiber treatment, coatings, and additives result in distinct grades. Some of the most common varieties of paper and how they differ in production and characteristics are given below.

Newsprint: Light in Weight and Low-Cost

Production: cheap and quick production of newsprint from wood that is mechanically pulped produces a product which is not very strong but is highly absorbent.

- Features: light, thin, uncoated, temporarily used, designed for use with newspapers, leaflets, and advertisement inserts.

- Sustainability: Typically constructed of high levels of recycled fiber, low environmental load.

Office Paper: Smooth and Versatile

Production: Usually produced using chemical pulping to remove lignin, making a stronger and more durable paper. It is further refined for an even, silky texture.

- Features: In several weights (e.g., 70-100 GSM), office paper is print-ready, suitable for writing and photocopying, with balanced brightness and ink absorption.

- Variations: Can be available in premium, coated, or recycled types for optimal performance and environmental sustainability.

Cardboard: Thick and Durable

- Production: Constructed from a number of layers of pulp that are pressed against each other, at times supplemented by recycled fibers for added thickness and strength.

- Features: Strong and rigid, cardboard is widely used for packaging, shipping boxes, and reinforcement. Corrugated cardboard includes fluted interior layers for increased cushioning.

- Sustainability: Highly recycled and often produced from post-consumer waste.

Coated Paper: Enhanced for Printing and Graphics

- Production: Coated with materials like clay, calcium carbonate, or polymer to create a smoother and reflective finish.

- Features: Gloss, matte, or satin finishes are offered by coated paper, which can enhance the sharpness and brightness of colors and can be utilized to print magazines, brochures, and better prints.

- Limitations: Lower absorbency that makes it unhelpful for regular pen writing and high-speed printing processes.

Recycled Paper: Environmentally Friendly and Sustainable

- Production: Made from waste paper collected while being used, treated to detach ink and trash before being re-pulped and remanufactured.

- Features: Can alter from standard in terms of brightness and texture since it depends on the addition of virgin fiber while it was being produced. Contemporary recycled paper ensures high quality in addition to smaller environmental impacts.

- Applications: Often integrated into notebooks, boxes, and eco-friendly printing products.

Every type of paper is suited to a specific application, balancing competing factors like cost, durability, and sustainability. New production technology further extends the potential for specialist and sustainable paper solutions.

Environmental Impact of Paper Production

The paper sector is crucial to modern society, yet its production has significant environmental impacts. Ranging from deforestation and water consumption to energy usage and carbon footprint, traditional paper making procedure has sustainability concerns. However, the sector is evolving with efforts to reduce its footprint through recycling, responsible sourcing, and innovative eco-friendly materials.

Deforestation and Resource Consumption

Pulp and paper industry has long relied on wood pulp, leading to mass deforestation except when done sustainably. Loss of forests is harmful to biodiversity, contributes to global warming, and ruins ecosystems. In addition to deforestation, the process is resource-intensive, consuming a lot of water and energy. Water is utilized for pulping, processing, and bleaching, while energy – largely derived from fossil fuels – is a source of greenhouse gas emissions.

Pollution and Waste Management

Chemical pulping emits toxic pollutants like dioxins and sulfur compounds that pose serious environmental risks. Papermaking waste and residues in the absence of waste management accumulate to lead to landfill overflow and pollution. The improper use of chemicals and poor disposal methods further exacerbate the environmental impacts of the industry.

Recycling and Responsible Sourcing

Efforts to reduce the environmental footprint of pulp and paper making have become more common, with recycling playing a vital role. Paper recycling requires less material, reducing pollution and forest destruction. Post-consumer recycled content is standard in most paper products, with high rates included. Sustainable forestry management programs such as those offered by the Forest Stewardship Council (FSC) and the Sustainable Forestry Initiative (SFI) provide responsible sourcing through replanting and the preservation of biodiversity.

Alternative Sources of Fiber

In addition to the traditional paper wood pulp, alternative fibers such as bamboo, hemp, and crop waste offer a sustainable alternative. These fast-growing renewable resources consume less land and water and provide a renewable alternative that reduces the dependence on the traditional forests.

Chlorine-Free Bleaching

The application of chlorine-free bleaching technologies, such as elemental chlorine-free (ECF) and totally chlorine-free (TCF) processes, has been a significant reduction in the emission of harmful chemicals into water bodies. They cause the least damage to the environment and help maintain paper quality.

Biodegradable and Compostable Paper

Advances in biodegradable and compostable paper technology are now allowing the use of plant-based additives and coatings with less landfill waste. These sustainable treatments cause paper products to decompose naturally, reducing long-term environmental impacts.

Energy-Efficient Manufacturing

Paper plants are rapidly adopting renewable energy options such as wind, solar and biomass, which significantly reduce their carbon footprints. Closed-loop water systems also reduce water pollution and overall consumption, making manufacturing more durable. With the ever-increasing demand for paper, change for durable operations and technology is the way to reduce environmental decline. Recycling, fair sourcing, and environmentally friendly products are some ways that customers and businesses can contribute to the future paper industry to make it a greener place.

Paper Production with AMED

The papermaking business has been completely transformed by advanced manufacturing technologies with improved efficiency, sustainability, and quality of product. AMED, being at the forefront in developing new and innovative paper manufacturing business solutions, is driving such development, dictating the direction towards green and high-performance paper making.

Papermaking Technologies

AMED, a paper production company, harnesses cutting-edge technologies in its papermaking system to maximize yields while minimizing the paper industry’s environmental impact:

- Automated Pulping Systems: Advanced pulping technology allows effective fiber refinement, reducing waste and energy consumption.

- AI-Driven Quality Control: Smart monitoring systems employ artificial intelligence to detect flaws and adjust processing parameters in real time, generating uniform paper quality.

- Water and Energy Efficiency: AMED uses closed-loop water recycling systems and energy-efficient drying technologies, reducing overall resource consumption.

- Eco-Friendly Coatings and Treatments: Innovative, plant-based coatings eliminate chemical treatments and make paper more sustainable without compromising on performance.

The Role of Paper in an Evolving World

Despite technological advancements, paper remains an essential material for communication, packaging, education, and business. High-quality and sustainable paper demand continues to increase further underscoring the need for responsible manufacturing practices. Through innovation and responsive sourcing, the industry can balance efficiency with environmental stewardship.

AMED’s Role in Paper’s Future

AMED’s commitment to technological innovation and sustainability is shaping the future of paper production. Through leading-edge smart automation, sustainable materials, and environmentally friendly manufacturing processes, AMED is empowering manufacturers to produce paper that not only meets consumer needs but also the environment.

As industries and companies seek greener solutions, companies like AMED are demonstrating how the future of paper production lies with efficiency, innovation, and sustainability.