Water pumps are very essential appliances that find applications within industries, homesteads, and systems for dispensing water from one location to another. From irrigation pumping, and waste management to pumping requirements of building systems, good knowledge of the mechanics of the functioning of a pump ensures efficient usage and use for long operation. So, what is the best kind of pump?

In this article, we will break down the basic types of water pumps, the major components involved, and how they work in the transportation of water efficiently. Whether you are a homeowner looking to install a pump or a professional in need of more technical insight, this guide should help you understand the principles behind different types of pumps and how they keep water flowing where it is needed.

What is a Water Pump?

A water pump is basically a mechanical device used in raising, compressing, or transferring water from one point to another. By converting mechanical energy into hydraulic energy, water pumps make the movement of water in systems involved in irrigation, drainage, and industrial processes easy. This is crucial since the supply of water must be continuous and controlled; therefore, these pumps are important both at home and commercially.

There are different types of water pumps, all serving specific purposes and suitable for specific environments. Some water pumps work on the principle of centrifugal force, while others work on the principle of positive displacement or diaphragm action to ensure the water moves effectively. Whatever the type, the ultimate function of all kinds of water pumps is to provide the necessary force to transport water through pipes or channels often against gravity or other opposing pressures.

How does a Water Pump Work?

A pump for pumping out water is a very simple device that converts mechanical energy into hydraulic energy, which serves to raise the water from one point to another. Basically, all water pumps manage the movement of fluids using various components working as a team to achieve specified pressure and flow. Understandably, knowing how a water pump works involves knowledge of both the energy conversion process itself and the major parts the device consists of for operation efficiency.

Energy Conversion and Fluid Movement

The general operation of a water pump from the top water pump supplier essentially involves the use of mechanical power from an electric motor, engine, or other forms of manual power in the transfer of water. This is done through the conversion of the mechanical energy to the moving parts of the pump, resulting in pressure that actually acts to force water to move through the pump and into pipes or other forms of water distribution systems. Depending on the type of pump, the process of fluid movement may be different, but the ultimate goal is to push water from an inlet to an outlet, overcoming obstacles like gravity, pressure differences, or friction in pipes.

Key Components of a Water Pump

Several key components work in unison to make water pumps effective:

- Impeller: Most major types of water pumps feature the impeller as one of, or the most important part – especially for centrifugal-type systems. The impeller – a whirling disc or a wheel on which a set of impellers are mounted – transfers energy into the water by converting an attached motor’s energy into velocity. It creates a water flow towards the outlet and increases its velocity and pressure.

- Motor or engine: The motor or engine provides the mechanical energy required for the functioning of the pump. In the case of electric pumps, it is the motor that turns the shaft, further actuating the impeller or other mechanisms. In the case of engine-driven pumps, an internal combustion engine acts in place, usually in portable or heavy-duty pumping applications.

- Valves: They control the direction, pressure, and flow of water within the pump system. For instance, check valves avoid backflow, while discharge valves control the release of water. These parts ensure the efficient and safe passage of water through the system, avoiding any damage or undesirable reversal of the flow.

Pump housing: The housing covers the inner components of the pump, such as the impeller, and directs the flow of water. It provides structural integrity and smooth passage of water.

How Various Types of Pumps Work

Different types of pool pumps create water movement with somewhat varied mechanisms to accomplish this:

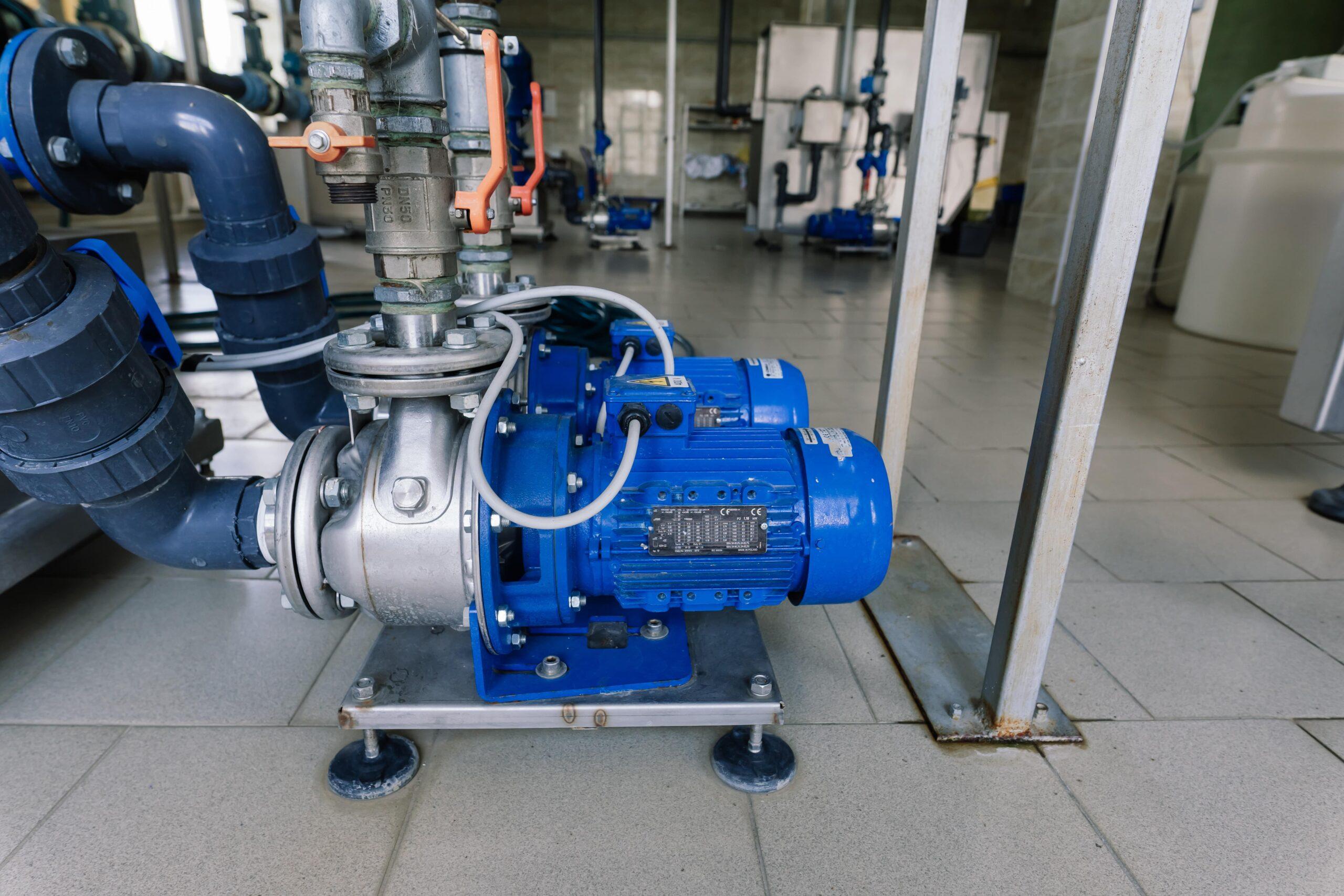

Centrifugal Pumps

These pumps work on the principle of an impeller that rotates at high speed, creating centrifugal force to push the water away from the center and out through the pump’s discharge pipe. They find their usage in areas where a high flow rate is required, like water treatment plants or irrigation systems.

Positive Displacement Pumps

These pumps move water by entrapping a specific volume of liquid and forcing the liquid into the discharge pipe at each stroke. Their most common type is the diaphragm pump, which generally has a diaphragm that acts as a shuttling valve, attracting and pressing the water by its movements. They are very suitable for pumping high-viscosity liquids where the accuracy of flow becomes necessary.

Submersible Pumps

These pumps are designed for operation submerged in the fluid to be pumped. The motor is sealed within the casing to prevent water from seeping into it, while the impeller pushes water up through the discharge pipe. In general, submersible pumps are applied in wells, sewage systems, and flooded areas.

Gear Pumps

A gear water drainer utilizes two interlocking gears to capture and transport water in a particular manner. During rotation, it allows for the creation of a partial vacuum, which pulls water into the pump chamber, where it is forced out at pressure. These kinds of pumps are applicable in high-pressure applications and also in viscous fluids.

Types of Water Pumps

The water pump designs vary in application and environment. There are mainly two general types of water pumps: centrifugal pumps and positive displacement pumps. Each has a unique characteristic that best fits specific tasks depending on the particular volume, pressure, and flow requirements of the job. These include the following.

Centrifugal Pumps

Centrifugal pumps are among the common water pumps used. Centrifugal force is the principle of operation of the pump, whereby the water is drawn into it and, by the spinning action of the impeller, it is pushed outwards.

Operation

Water enters the pump through an inlet and is directed into the center of the rotating impeller. The rotation of the impeller accelerates the water, forcing it outside the impeller area toward the pump discharge pipe. The kinetic energy from the spinning impeller converts into pressure that pushes the water through the system.

Centrifugal pumps are ideal for moving large volumes of water at moderate pressures and are widely utilized in applications like irrigation, drainage, and industrial water systems.

Key Benefits

- High flow rates.

- Efficient in the transfer of large volumes of water.

- Simple construction makes them easy to maintain.

Common Applications

- Water supply systems.

- Agricultural irrigation.

- Industrial processes and cooling systems.

Positive Displacement Pumps

Positive displacement pumps operate by entrapment of a fixed amount of water and forcefully pushing it through the pumping system. They are capable of handling high-pressure applications and maintaining flow without change with respect to system pressure variations.

Operation

In positive displacement pumps, a diaphragm, piston, or gear mechanism moves water through a chamber and displaces a set amount with each stroke or revolution. The result is a consistent flow rate and high-pressure output, even if the discharge valve is closed or the system is partially blocked.

These pumps and water pump accessories are normally used for viscous fluids or systems where a steady flow is required, even under varying pressures.

Key Benefits

- Provide a constant flow at higher pressures.

- Handle wide ranges of fluids, such as viscous, slurry, and abrasive liquids.

- It is ideal for precise fluid metering and higher-pressure pumping.

Common Applications

- Chemical processing and fuel transfer

- Oil and Gas Industries

- Food and beverage industries – for precision in fluid flow control.

Water Pumps at AMED-US

At AMED-US, we have a wide variety of water and wastewater pump and thermostat services in stock, including superior quality to meet many industries and applications. Be it a centrifugal pump for high-flow water transfer, a positive displacement pump for applications requiring precision and high pressure, or any other kind of pump, we have your solution. Our range of pumps is suitable for irrigation, wastewater treatment, industrial processes, and much more.

With our team of pump experts ready to take you through our selection to ensure that you get just the right pump for your particular needs, we realize that every pumping system is different, and we are here to give personalized advice and recommendations on how to best set up your system.

Whether you will be making a purchase or would like our experts to help you in choosing a pump, please do not hesitate to contact us. Our experienced staff can provide detailed information on products, installation, and maintenance, and can even assist in getting quotes for your project.