Equipment choice in large-scale food production, manufacturing, or scientific applications makes the difference in efficiency and quality. Among the many that exist for such purposes, two of the most confused are industrial blenders and industrial mixers. While both are used to blend and combine ingredients, they serve very different purposes.

Knowing the key differences between these two will, therefore, help you in picking the right tool for the specific need, whether you need to mix heavy dough in industrial baking or blend ingredients to achieve smooth and consistent liquids. In this article, we look at the core differences, applications, and benefits of each industrial blender to help you go about making an informed decision for your business or production process.

What is an Industrial Blender?

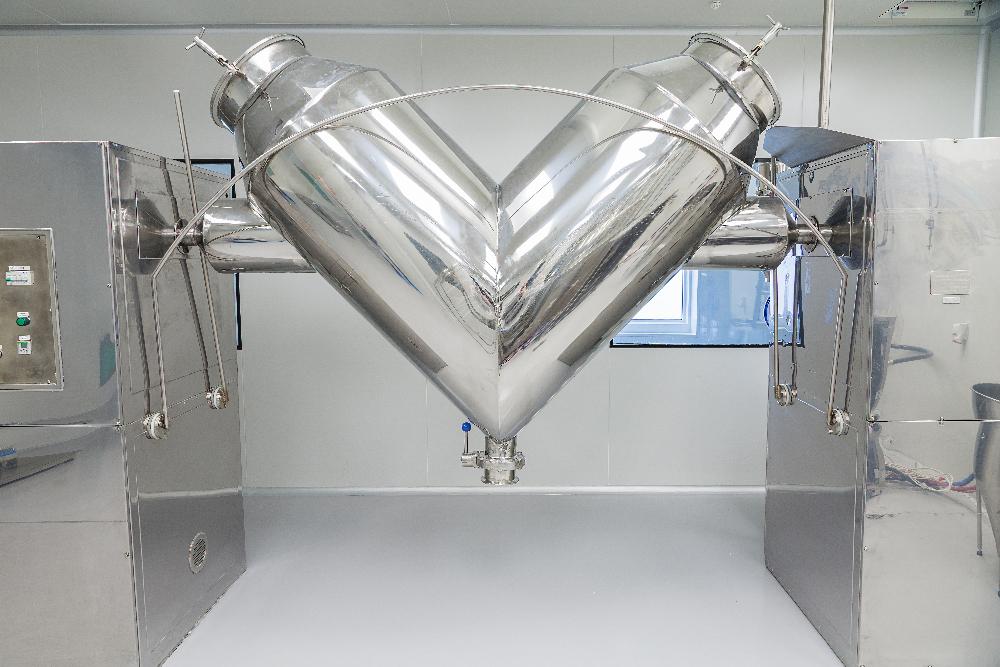

The main difference with an industrial blender, which includes a strong and powerful piece of equipment designed to mix, blend, or emulsify in large batches, generally comes into function within industries needing such liquid processing, pastes, or even powders. In contrast, the chief function of an industrial mixer or agitator would be to reach a uniform, smooth blend, which can also make a blender highly crucial to applications concerning texture and uniformity as foremost. These blenders use different mechanisms, like blades, impellers, or agitators, that provide efficient breakdown, combining, and emulsification of ingredients.

Main Functions of Industrial Blenders

- Blending: This is the combination of liquids, powders, or pastes to produce a uniform product, such as smoothies, sauces, or chemical formulations.

- Emulsification: The homogenization of two immiscible liquids, such as oil and water, into a stable emulsion. This is achieved in many cosmetic, pharmaceutical, and food applications.

- Homogenization: Making the consistency in a mix uniform; highly important in such food products as dairy and beverages, also in pharmaceuticals.

- Mixing dry ingredients: There are some applications whereby an industrial blender can manage dry powders, like spices, flour, or pharmaceuticals, and make a consistent mix that would later be reprocessed.

Industrial Blender Machine Uses

- Food processing: Blenders find extensive application in food manufacturing to mix ingredients such as sauces, soups, salad dressings, beverages, or baby food. They assure a consistent and quality result, be it blending fruits and vegetables for smoothies or creating emulsions for creamy spreads.

- Pharmaceuticals: Blenders in the pharmaceutical industry are employed for the mixing of active ingredients with excipients and binders to achieve uniform drug formulations, such as tablet powders or suspensions.

- Cosmetics and personal care: Blenders in the cosmetics and personal care industry manufacture products such as creams, lotions, shampoos, and many other products of smooth and consistent texture.

- Chemicals and paints: Mixers in these industries blend different chemical compounds, pigments, and solvents to make paints, coatings, and other chemical preparations.

Materials Handled by Industrial Blenders

Materials handled by industrial blenders vary based on the design of the blender and for what use it is intended. Some common materials used by a professional blender manufacturer include:

- Liquids like oils, water, and beverages.

- Powders such as flour, spices, sugar, and pharmaceutical ingredients.

- Pastelike materials for sauces, dressings, and some kinds of creams.

- Granular materials for products such as chemical compounds, detergents, or cosmetics.

What is an Industrial Mixer?

An industrial mixer is a heavy-duty machine designed to mix two or more ingredients, whether solid, liquid, or both, into a homogenous mixture. Industrial mixers are an indispensable part of the manufacturing process that involves mixing or blending ingredients at large scale. Whereas the industrial blender is usually set up for a liquid-based or emulsified product, the industrial mixer has the capability of combining nearly any type of substance together, from solid to liquid, making them more versatile in some applications.

Primary Role of Industrial Mixers

The primary purpose of a commercial mixer from the top mixers manufacturers is to promote the efficient blending of ingredients so that a uniform consistency is achieved throughout a batch. In many processes, ingredients should be uniformly distributed without necessarily being broken down or emulsified, as in the case of blending. Materials are mixed in various stages of production, including:

- Dry mixing – e.g., powders, granules, and solids.

- Wet mixing, such as the incorporation of liquids into dry ingredients.

- Mixtures of solids and liquids, such as the blending of a powder with a liquid to form a paste or slurry.

- Powder-liquid mixtures for products like detergents or adhesives.

Industries That Use Industrial Mixers

Industrial mixing bowl is used in a variety of industries, including:

- Food and beverage: Mixers play a very important role in the production of food, ranging from mixing dry ingredients like flour, sugar, and spices to incorporating liquids into dough or batters. Examples are bakery dough mixers, drink mixers for soft drinks, or salad dressing mixers.

- Pharmaceuticals: Mixers within the pharmaceutical industry are meant for mixing active ingredients with excipients and other powders or liquids for tablet manufacturing, ointments, syrups, or creams.

- Chemicals and paints: Mixers are an important part of the preparation of various chemical formulations, paints, coatings, adhesives, and sealants. The ability to mix resins, pigments, and solvents uniformly ensures the desired texture and consistency.

- Cosmetics and personal care: Industrial mixers are used to mix ingredients for creams, lotions, shampoos, and other personal care products, ensuring smooth and consistent textures while preserving product integrity.

- Agriculture and fertilizers: Mixers are used to combine solid and liquid chemicals in the formulation of fertilizers, herbicides, and pesticides.

Materials Handled by Industrial Mixers

Industrial mixing application can handle a diverse range of materials, including:

- Solids can be in the form of powders, granules, pellets, or flakes. The above-mentioned materials mostly require special mixers such as ribbon blenders or paddle mixers to ensure even distribution.

- Liquids include oils, water, milk, or syrup and are usually combined with dry ingredients.

- Pastelike or slurry materials, including both solid and liquid phases, could be found in adhesives, heavy coatings, or wet granulation in pharmaceuticals.

- Granules and fibers within industries such as agriculture-mixers may be dealing with fertilizers or animal feeds.

Main Differences Between Industrial Blender and Mixer

Industrial blenders and mixers services play distinct roles in manufacturing, with each designed for specific tasks based on the type of materials and desired outcomes. Understanding their differences in functionality and material compatibility is key to selecting the right equipment for your production needs.

Industrial Blenders

Blenders are primarily designed to combine and emulsify liquids, powders, or pastes into a uniform, consistent mixture. They are best suited for applications where uniformity in texture and consistency is critical, such as in food processing, pharmaceuticals, or cosmetics. Such industrial blender heavy duty often uses blades, impellers, or high-speed rotation to break down particles and mix ingredients well. Their functionality makes them ideal for achieving:

- Smooth textures in sauces, soups, and beverages.

- Emulsification – making stable mixtures of oil and water.

- Homogenization of liquid-based products, such as creams and lotions.

Blenders are ideal for applications requiring high levels of integrations and smooth consistencies, including liquids such as oils, syrups, water-based solutions, or milk. Fine powders include spices, protein powders, and pharmaceutical ingredients. Pastes are those products which have to come out with smooth textures, such as sauces, creams, and spreads.

Industrial Mixers

Mixers, by contrast, are great for mixing solids, liquids, or a combination of the two mixer attachments into a consistent product. Unlike blenders, mixers often work with heavier or more complex ingredients, like doughs, pastes, or granulated materials. They are fitted with paddles, agitators, or rotating arms designed to mix ingredients thoroughly without necessarily breaking them down. Mixers are perfect for:

- Mixing heavy materials like dough or batter.

- Combining solids and liquids to form slurries or pastes.

- Creating evenly distributed mixtures of dry powders or granules.

Mixers are at their best when handling bulkier, more complex materials that require extensive distribution without substantial breakdown:

- Dry solids: flours, granules, powders, and pellets.

- Solid-liquid combinations: Doughs, batters, or slurries.

- Heavy or dense materials: Adhesives, thick coatings, or fertilizers.

- Granular and fibered materials: Agricultural products like animal feed or chemical formulations.

Choose the Right Equipment for Your Business with AMED-US

At AMED-US, we believe that the right equipment, be it a commercial blender or an industrial mixer, is vital to the effectiveness and quality of your production process. Your operation’s success is based squarely on how well the equipment matches your specific materials, production volume, and desired end result.

Assess Your Materials

Identifying the types of materials you work with is the first step in selecting the appropriate equipment. In this case, if a high amount of liquid-based or even fine powder ingredients is usually needed in your production process, a blender would act accordingly. Blenders are designed for materials that have to result in a smooth consistency, emulsification, or homogenization. If the products have a more solid base and combine with liquids to become doughs, batters, slurries, and the like, a mixer will do the required job of blending thoroughly but not overworking the ingredient mix.

Consider Production Volume

Your production volume also plays a major role in determining the type of equipment you need. From small batch models to large-scale systems, industrial blenders and mixers come in a wide range of sizes. In case you are working with big quantities of materials, you will need equipment that can support such volume without compromising performance or quality. Where small batches or specialty products may require mixing/blending, one can look at smaller but capable mixers/blenders instead.

Understand the Process Needs

Think of your production’s specific goals and process requirements. Do you need to make a smooth, uniform product with high integration? Then, the blender is the right choice. But if you work with heavier or thicker materials, and the need for more intense mixing action without over-processing is higher, then the mixer will likely be a better fit.

Contact the professional Industrial Equipment Supplier to know more information.