The diaphragm pump is versatile, dependable, and can be found in chemical processing, and water treatment, among other areas. These kinds of pumps services are famous for their ability to handle viscous fluids that are usually thick, their self-priming capabilities, and their ability to operate in harsh environments. But how do diaphragm pumps work?

In this article, we look at how this efficiency in pumping technology works out its major components, principles of displacement, and reasons it’s favored in fields. Whether you are working with diaphragm pumps professionally or are simply intrigued by how they work, this guide will give a clear understanding of their mode of operation and benefits to anyone reading it.

What Are Diaphragm Pumps?

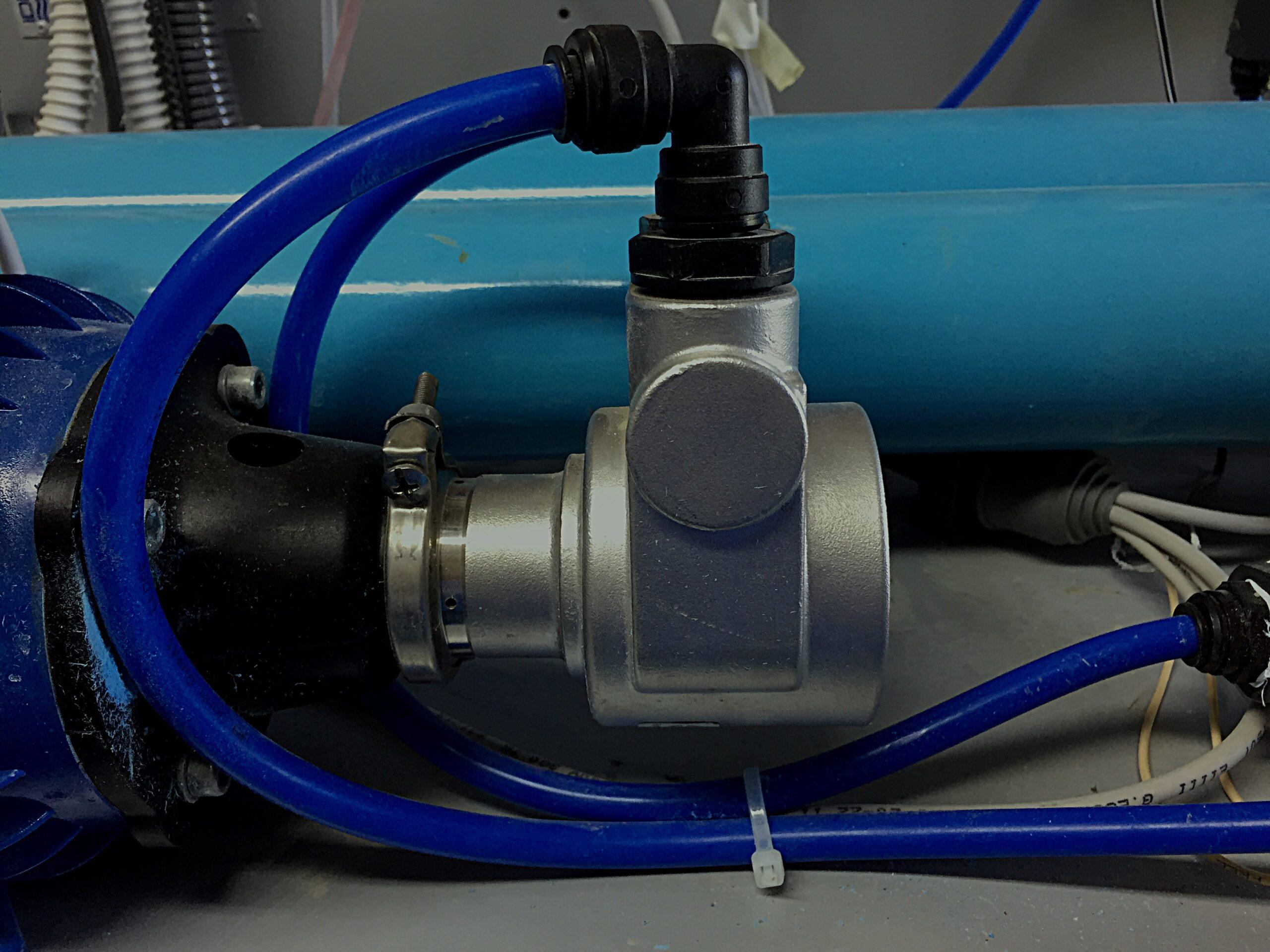

Diaphragm pump applications are a type of positive displacement pump that moves fluids in a system by the use of a flexible diaphragm. Unlike centrifugal pumps, which achieve fluid movement by the centrifugal force of spinning impellers, diaphragm pump parts operate by the simple principle of repetitive expansion and contraction of a diaphragm to provide a suction and discharge action. This mechanism allows diaphragm pumps to move a fixed volume of fluid with each stroke, making them ideal for precise and consistent fluid transfer.

Probably the most impressive feature of diaphragm pumps is the wide variety of fluids with different properties that they can handle: viscous, corrosive, abrasive, and slurry-like-these are just a few examples of difficult fluids for which diaphragm pumps are designed without the risk of clogging or wear that may affect other types of pumps. Their construction allows them to transfer thick liquids, chemicals, food products, and even slurries containing solid particles. The flexible diaphragm creates a sealed environment, preventing leakage and ensuring safe handling of hazardous or volatile materials.

All of these features make diaphragm pumps ideal for industrial applications in chemical processing, pharmaceutical manufacturing, mining, and water treatment, as they can handle a great variety of fluids with extended flow rates and pressures. Again, other additional beneficial reasons include their ability to operate dry, self-prime, and handle difficult pumpable products without damage, which extends their use across a wide range of applications.

How Do Diaphragm Pumps Work?

A diaphragm water pump is a very simple, effective pump relying on the principle of two flexible diaphragms. These move back and forth in a reciprocating motion to create alternate suction and delivery chambers, respectively. The action of moving the diaphragm may be actuated either by air pressure or mechanical drive, depending on the pump design.

Press Stroke and Fluid Expulsion

Electric diaphragm pump operation is the reciprocating motion that acts at the heart of the mechanism. During a press stroke, the movement of diaphragm that is, a first diaphragm-reduces the chamber volume and thus forces the fluid out of the pump. It expels the liquid through a discharge valve into a system. During a press stroke, the pressure that propels the fluid through a pipeline – whether it is a liquid, slurry, or gas-is produced.

The Suction Stroke

One membrane of diaphragm one throws out fluid, while a second one, diaphragm two, moves in reverse and, therefore, develops a suction stroke. Due to its outward movement in the negative phase, diaphragm two expands the volume within the chamber, creating negative pressure or vacuum. This in turn allows sucking of the fluid into the pump via the inlet valve. With this stroke, the flow of liquid at one continuous end is kept, which is thrown outside with the next stroke related to diaphragm one.

Airflow Reversal for Continuous Operation

The air-operated diaphragm pump requires, for continuous operation, an air supply (in air-operated diaphragm pumps) that reverses direction with each stroke. Air enters the air chamber of the pump, forcing diaphragm one forward to extrude the fluid. When diaphragm one completes its press stroke, the airflow reverses itself and forces air-operated diaphragm pump two to move outward, siphoning more fluid into the chamber. This back-and-forth action – powered by the alternating flow of air – ensures a steady, uninterrupted transfer of fluid, making diaphragm pumps efficient and reliable for many industrial applications.

By using this reciprocating motion and alternating press and suction strokes, diaphragm pumps can handle various fluids with ease, providing high performance and consistent flow rates throughout their operation.

AMT Diaphragm Pumps

AMT pump is a highly regarded manufacturer of high-quality diaphragm pumps that are engineered for durability, efficiency, and reliability. With a strong reputation in the pump industry, AMT pump parts provide a range of diaphragm pumps suitable for various industrial and commercial applications. These pumps are designed to meet the high demands of industries such as chemical processing, water treatment, agriculture, and mining, among others.

One of the major advantages that come with the AMT pump wiring diagram is its solid build, which ensures a lifetime of performance under even very harsh conditions. Constructed from high-quality materials with advanced engineering, AMT pumps can handle corrosive chemicals, viscous liquids, and abrasive slurries without sacrificing performance.

Other key benefits of AMT from the top diaphragm pump manufacturers involve efficiency. Designed to provide accurate fluid transfer with very low energy consumption, these pumps have positive displacement principles that ensure the same volume of fluid is pumped with each stroke. This allows consistent flow rates and pressure-essential elements in many industrial applications. Another convenient feature of diaphragm pumps with AMT is the self-priming capability, which further enables operation in both horizontal and vertical positions without ancillary systems for priming.

Another contributing advantage is that AMT diaphragm pumps are fairly easy to maintain. They are simply designed, resulting in fewer moving parts prone to breakdowns, thus enabling quicker and easier execution of maintenance tasks. As such, they are certain units of operation that do not want an operation to experience any downtime and are interested in ensuring that their line of production is up and running.

Key Benefits of AMT Diaphragm Pumps

Following are the major benefits of the AMT diaphragm pumps:

- Sturdy Build: AMT pumps are fabricated with quality materials so that they stand up against the harshest environment. Strong in structure, these serve for very long periods in industries operating with hazardous chemicals, and viscous, or abrasive fluids.

- Efficiency: AMT diaphragm pumps are designed for high-efficiency fluid transfer with minimal energy consumption. Their positive displacement design ensures that the same volume of fluid is moved per stroke, providing consistent flow rates and pressures critical in many industrial applications.

- Self-Priming Capability: These pumps can also be rated as self-priming since their operation does not depend upon any additional priming mechanisms. This further extends the positioning flexibility, which can be used either horizontally or vertically according to different installation sites’ needs.

- Low Maintenance: Besides having fewer moving parts, AMT diaphragm pumps have a very simple design and hence require little maintenance. The strong build minimizes chances of breakdown, while regular maintenance tasks are easy to perform and take the shortest time possible to minimize your operation downtime.

- Versatility: AMT diaphragm pumps can work with high-viscosity fluids to more abrasive slurries, thus making them ideal for industries that deal with such materials. That again extends to application both in clean and contaminated environments for diverse industrial needs.

- Aggressive Media Resistance: Be it extreme temperature, high pressure, or an environment with corrosive agents, AMT diaphragm pumps are designed to assure reliable operation in harsh conditions and long service life with minimal repair needs.

Diaphragm Pumps at AMED-US

At AMED-US, the AMT pump company, we have some of the finest quality diaphragm pumps from well-known and reliable manufacturers such as AMT. Our pump experts can easily guide you through selecting a proper diaphragm pump for your needs. From corrosive fluids to high-viscosity and abrasive slurries, our experience will help guide you in the selection process to make sure you have the most efficient and reliable pump for your application.

We realize that selecting the right pump is not an easy task, and our experts are available for any questions. From advice on installation and maintenance to troubleshooting and custom solutions, AMED-US, the leading ATM manufacturer, is committed to excellent customer support at every step of your pumping needs.

Whether you are looking for a high-performance diaphragm pump that can take on the most demanding jobs or want consultation on how to maintain and optimize it, don’t hesitate to reach out. Our team at AMED-US is here to ensure your pumping system operates smoothly, efficiently, and reliably.

For more information or assistance with your diaphragm pump needs, please contact us today. We are here to help guide you in the best direction for your business.