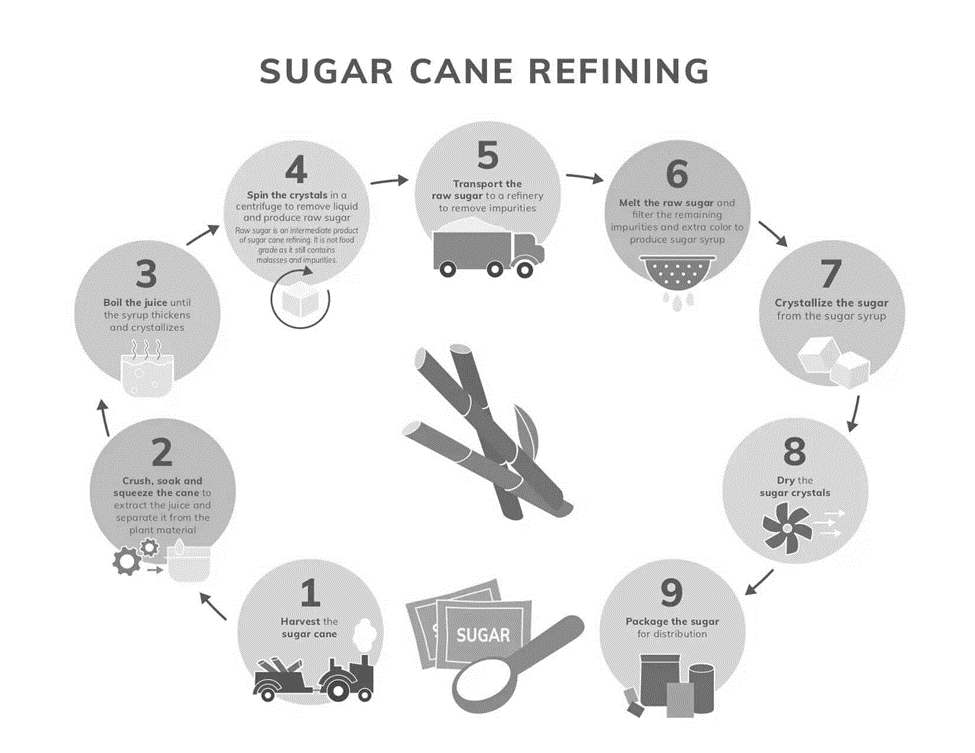

Table sugar comes from sugar cane, a tropical plant growing up to 20 feet tall and producing sucrose via photosynthesis. Milled sugar includes impurities such as molasses, plant debris, and salts. So, sugar cane refining (affination, carbonatation, and decolorization) helps make pure, edible sugar. Further, tropical North Queensland, northern New South Wales, Florida, Louisiana, and Texas in the US, Brazil, India, and Thailand are key sugar cane producing and refining areas.

Sugar Cane Growth and Harvesting

- Description of Sugar Cane as a Tropical Grass: Sugar cane is a tropical grass that might grow up to 6 meters tall. It has thick, fibrous stalks rich in sucrose for sugar production.

- Ideal Growing Conditions: Ideal conditions are warm, sunny climates free from frost and temperatures between 25-35°C. Soil should be well-drained and fertile for a pH level of 6-7 and require about 1500-2500 mm of rainfall annually or equivalent irrigation.

- Regions of Cultivation: In Australia, Northern New South Wales and tropical North Queensland grow sugar cane. India’s Uttar Pradesh and Brazil’s Central-South are others.

- Process of Planting and Growing Sugar Cane: Setts, stalk segments with 2-3 buds, propagate sugar cane. It matures about 9-24 months, depending on variety and habitat.

- Harvesting Methods: In many countries, the cane is harvested manually using machetes. Automated harvesters are being utilized to chop cane into billets and gather them in hours.

Initial Processing at the Sugar Mill

- Transportation of Harvested Cane to the Mill: Trucks, trains, and barges deliver harvested cane. Less time to processing prevents sucrose inversion and microbial growth.

- Weighing and Shredding of Cane Stalks: Cane is weighed on calibrated scales upon delivery for accuracy. Next, shredders split stalks into fibrous bits to increase cell exposure.

- Juice Extraction through Crushing and Milling: Roller mills crush the shredded cane, extracting the juice. A countercurrent of water (imbibition) boosts extraction efficiency.

- Removal of Impurities (Using Lime and Heating): Juice is treated with lime and heated to 105°C. It precipitates impurities, including calcium carbonate, which are filtered out.

- Concentration of Juice into Syrup: The clarified juice is concentrated in multiple-effect evaporators. Hence, it increases sucrose concentration from 15% to almost 60%.

- Initial Crystallization and Separation of Raw Sugar from Molasses: Syrup is seeded with fine crystals and vacuum evaporated. As a final point, centrifuges separate raw sugar crystals from molasses, which yields 96-98% sucrose raw sugar.

Transportation and Storage of Raw Sugar

Based on location and infrastructure, barges, trains, and trucks convey raw sugar to refineries. Barges lower handling costs for huge quantities via waterways. Rail suits long-distance overland transport and has great capacity. Trucks are valid for shorter routes or locations lacking rail. Raw sugar is kept in climate-controlled facilities to stop microbial growth. To suppress microbial activity, such warehouses have low humidity and temperatures below 25°C. Sugar is aerated and monitored for moisture below 0.25-1.10% throughout storage to avert clumping and fermentation. Automated loading and unloading decrease contamination for sugar purity until further refining.

Stages of Sugar Cane Refining

Affination

Adding hot, concentrated syrup to raw sugar eradicates the molasses layer. Softening molasses with this syrup renders separation more straightforward. Many early contaminants are removed by centrifugal devices that separate syrup from sugar crystals. Moreover, affination produces sugar liquor, a hot water-dissolved sugar solution suitable for filtration. Generally speaking, the step prepares raw sugar for the following stage while removing 50% of its color impurities.

Purification

Carbonation refers to the principal purifying procedure. Sugar liquor is treated with lime and carbon dioxide. That forms calcium carbonate precipitate. Precipitate catches gums, amino acids, and colorants. Such impurities are filtered away, which leaves the sugar solution more transparent. Remember, mill mud (the leftover solid) is not wasted and reused. As a soil conditioner, it replenishes nutrients in crops for greater sugar cane refining sustainability.

Decolorization

Decolorization clears liquor while eliminating color contaminants. It employs bone char, granular carbon, or ion exchange resin. Pyrolyzed animal bones make bone char, which absorbs color and ash due to its large surface area. Granular carbon from coal or coconut decolorizes well. Styrenic or acrylic ion exchange resins neutralize color contaminants and are flexible. Such processes make the solution transparent and practically pure before crystallization.

Crystallization

Crystallization helps turn clear liquid into sugar crystals. Originally, evaporators concentrate liquor while eliminating water. Ultraviolet light sterilizes the fluid and exterminates microbes. Vacuum pans lower boiling temperatures to prevent color development. Sucrose crystallization begins with seed crystals. Subsequently, the massecuite mixture is centrifuged to separate the sugar crystals from the syrup. Furthermore, after drying, sugar crystals are classified by size. Golden syrup and treacle are prepared from the residual syrup for enhanced resource usage.

Final Sugar Products and By-products

Sugar cane refining produces necessary products and byproducts for different sectors. The main product is white refined sugar—granulated, caster, and powder. Various quantities of molasses are added to white sugar to make light and dark brown sugar. Another key product is liquid sugar, including syrups. As mentioned earlier, the residual syrup after refining helps make golden syrup and treacle, which increases value and decreases trash. Bagasse and molasses are important byproducts. Sugar mills create power while burning bagasse, the fibrous leftover from crushed cane. Nutrient-rich molasses is used in animal feed, alcohol fermentation, and medications.

Sustainability and Environmental Considerations

Recycling and reusing byproducts cut waste and environmental impact in sugar refining. Sugar mills and local villages use bagasse as a renewable energy source. The refining process also yields molasses for animal feed, distilleries, and bakeries. To recover sucrose and prevent water waste, sweetwater from refining is recycled. In particular, filter carbon is refilled and reused for a lower environmental impact. Ion exchange resins and vacuum pans strengthen resource and energy use for better efficiency. Such initiatives keep sugar cane refining ecologically benign and profitable.

Contact us with any questions about sugar cane refining or for additional assistance.