John Crane Manufacturer

Innovative and leak-protecting John Crane seals can easily deal with high pressure and extreme temperatures to ensure the smooth running of all sorts of motors being designed for industrial purposes so they can meet all operational needs. Since the range of John Crane seals is diverse, one thing never changes that is their reliability in preventing leaks and efficiency.

High-Quality Seals: Durable & Reliable Solutions

At AMED-US, a great number of seals for industrial applications in industry are at your disposal. From high-pressure applications to those with abrasive or hazardous materials selection seals provide the best performance, durability, and dependability. Refer to our seal types below and get the perfect solution for your machinery.

Multi-Lip Cartridge Seal

Multi-Lip Cartridge Seals are designed for very heavy-duty applications; hence, they are suitable for machinery intended to work under very high pressure or in abrasive conditions. These industrial seals and gaskets provide improved sealing capacity with multiple lips that help avoid leakage, thus allowing machinery to operate efficiently while minimizing maintenance. Their robust design makes them a top choice for industries like mining, pulp and paper, and chemical processing.

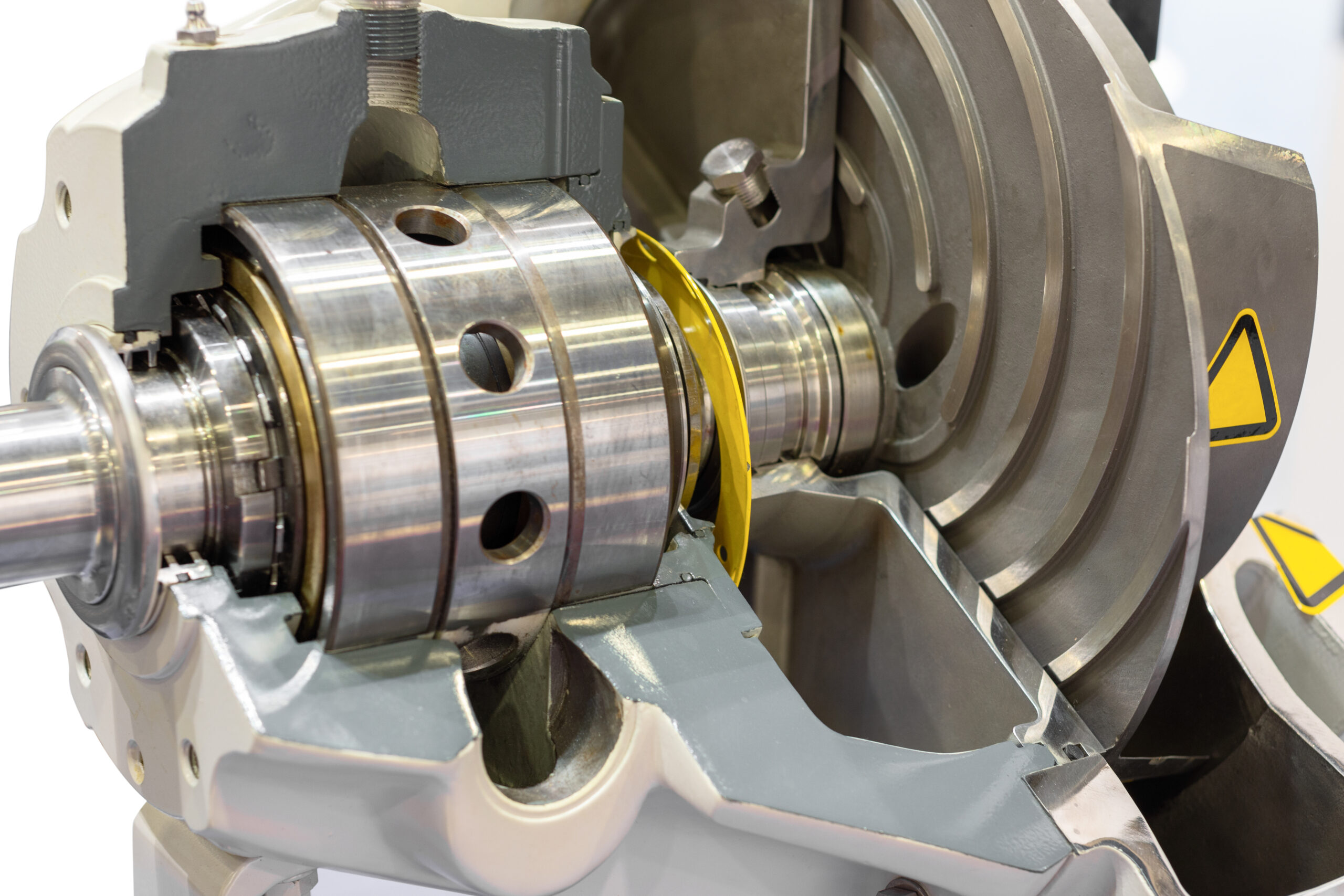

Gas Mechanical Seals

Gas Mechanical Seals are a non-contact seal that uses gas, normally air or nitrogen, as active media to create the seal barrier. For high-speed-rotating equipment like compressors and turbines, this seal’s performance is very effective without wear or contamination. The industrial mechanical seals must be recognized as providing longevity of equipment life and energy savings.

Mixer/Agitator Seals

The Mixer/Agitator Seals are designed to cope with the complicated motion of the rotating and oscillating shafts used in mixing and agitation. They do not allow the leakage of precious process materials and are fitted with ingenuity to perform under severe conditions in food processing, pharmaceuticals, and the production of chemicals. Their robustness ensures smooth running under demanding conditions.

Slurry Pump Seals

Slurry Pump Seals are designed to handle fluids that are highly abrasive and of high solid content, produced in the mining, mineral processing, and dredging industries. Their rugged construction allows them to have longer operation and minimize downtime in some of the harshest environments. These seals help in maintaining pump integrity in really tight situations.

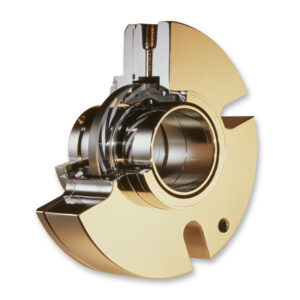

Dual Cartridge Seals

Dual Cartridge Seals provide two seals in one for added security against hazardous, toxic, or corrosive media. The seal’s applications are prevalent in the chemical, oil, and gas industries where reliability and environmental concerns are of most importance. The cartridge design makes the seal easier to install and maintain.

Edge Welded Metal Bellows

The design of Edge Welded Metal Bellows seals is aimed at very high-temperature and pressure applications. They provide superior flexibility and the required durability for long-term performance under the most adverse conditions in pumps and compressors for applications in industries like petrochemicals and power generation. Construction in welded metal offers complete leak-free sealing.

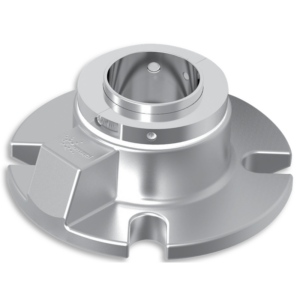

Single Cartridge Seals

Single Cartridge Seals offer a compact, fast, and easy to install unit for many general purpose applications. Very widely used on centrifugal pumps in water, wastewater and chemical applications. Design features combine the best balance between cost and performance.

Split Cartridge Seals

The Split Cartridge Seals are designed to be installed with ease, especially for huge machinery that is quite difficult to reach. They simply don’t need dismantling any equipment, thus saving hours and less maintenance time. Mostly used in large pumps and all types of heavy-duty equipment, split cartridge seals are employed where speedier seal replacement is a requirement.

Why Choose Seals of AMED-US?

With decades of industrial sealing expertise, AMED-US has established a reputation as a valued provider of high-performance sealing solutions. Our excellence is underpinned by expertise that is unparalleled in the industry, innovative design, and an unbending focus on delivering products exceeding performance expectations. We are proud of the key certifications that help to ensure our products meet the highest standards of safety, durability, and environmental compliance. Add to that the fact that we pride ourselves on relationships with top manufacturers and leading representatives who back up our claim of a solid, accurate operation.

Looking for industrial seal manufacturers? Choose AMES-US! When you partner with AMED-US, you are not just purchasing a product – you’re forging a relationship with a partner dedicated to helping your operations realize sustained performance even under the toughest conditions.

For more specific information on any of these products, or to place an order, don’t hesitate to reach out today, and let AMED-US help you find what you’re looking for: the right seal for your industrial application.

OUR SERVICES

Frequently Asked Questions

We provide repair services for expanded PTFE, compressed graphite, granulated elastomers, lip seals/radial shaft seals, mechanical seals, double seals, tandem seals, cartridge seals, and gas barrier seals.

Rod seals are used in hydraulic cylinders in construction machinery, such as excavators and bulldozers, pneumatic cylinders in manufacturing automation systems, and injection molding machines to prevent hydraulic fluid leakage.

Rotary seals are designed to seal the gap between a rotating and stationary component. They are used in hydraulic presses, aircraft landing gear, hydraulic jacks, wind turbines, food processing equipment, and mining equipment to prevent fluid or gas leakage and protect bearings from contaminants.

Our service procedures for industrial seals include inspection for wear or damage, cleaning the sealing surfaces, removing old seals, preparing and lubricating new seals, installing new seals, testing the equipment, regular maintenance inspections, and keeping detailed records of all inspections and replacements.

Teflon seals, made from PTFE, provide high chemical resistance and low friction. They are suitable for a wide range of temperatures and pressures, making them ideal for applications in chemical processing plants, pharmaceutical equipment, and high-temperature environments.