Hyundai Manufacturer

The Hyundai electric motors offered are advantageous for industries requiring exceptional performance, guaranteed reliability and high efficiency. Here you’ll find Hyundai electric motors of various kinds and configurations for different applications since the Hyundai electric company cares for both households and industrial workhorses to do tough and heavy-duty jobs.

High-Quality Electric Motors: Durable & Reliable Solutions

Electric motors are categorized into several types, each designed for specific applications and operational requirements. The main categories in our electric motor company include:

General Electric Commercial Motors

These are versatile motors suitable for a wide range of applications in both residential and light commercial settings. They are commonly used in household appliances, power tools, and small machinery.

Industrial Electric Motors

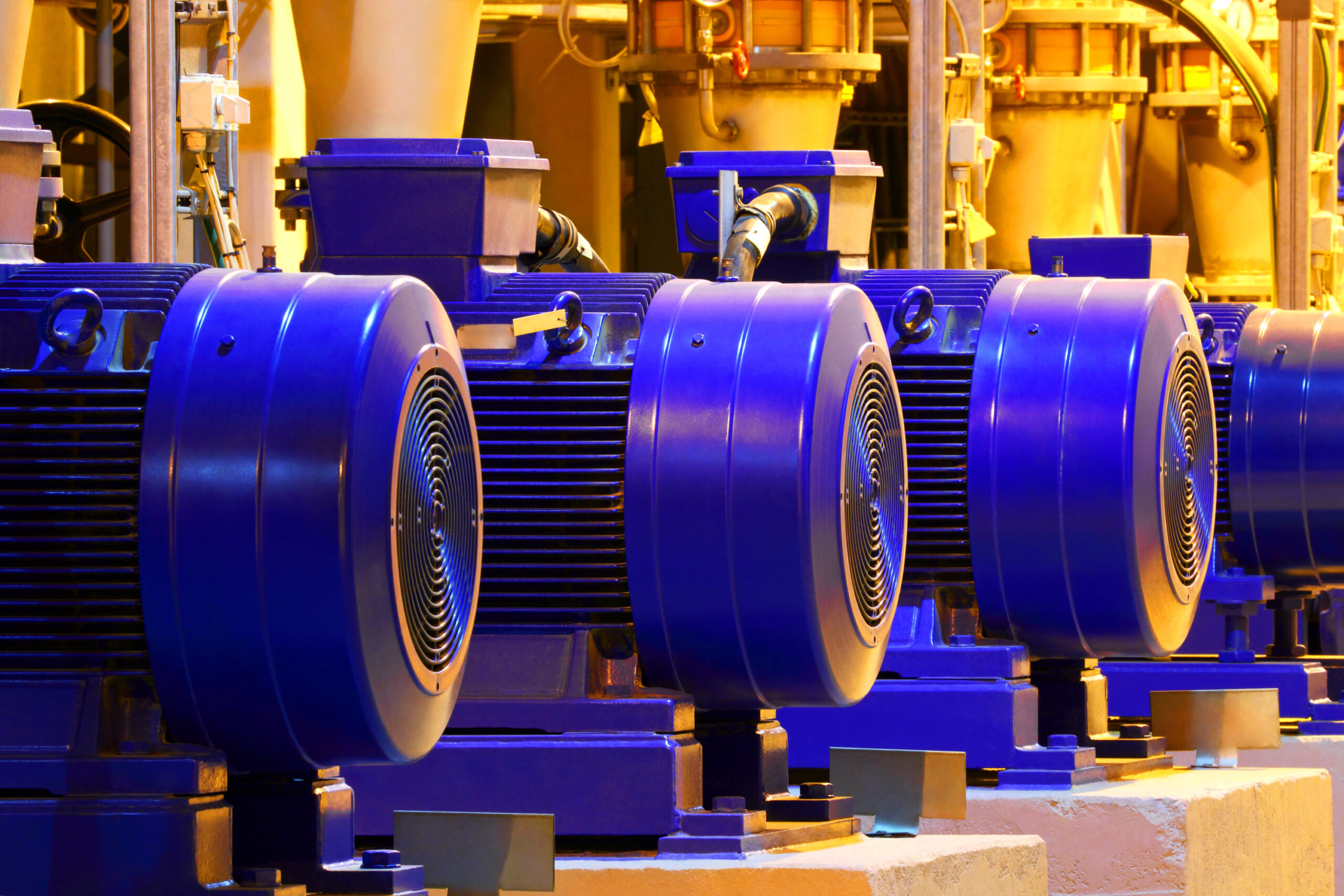

Designed for heavy-duty application of electric motors, they are built to withstand demanding environments and continuous operation. These motors are typically used in manufacturing plants, large-scale processing facilities, and heavy machinery.

Commercial Electric Motors

These motors occupy a middle ground between general and industrial motors. They are used in commercial buildings, HVAC systems, and medium-duty machinery in various business settings.

AC Motors

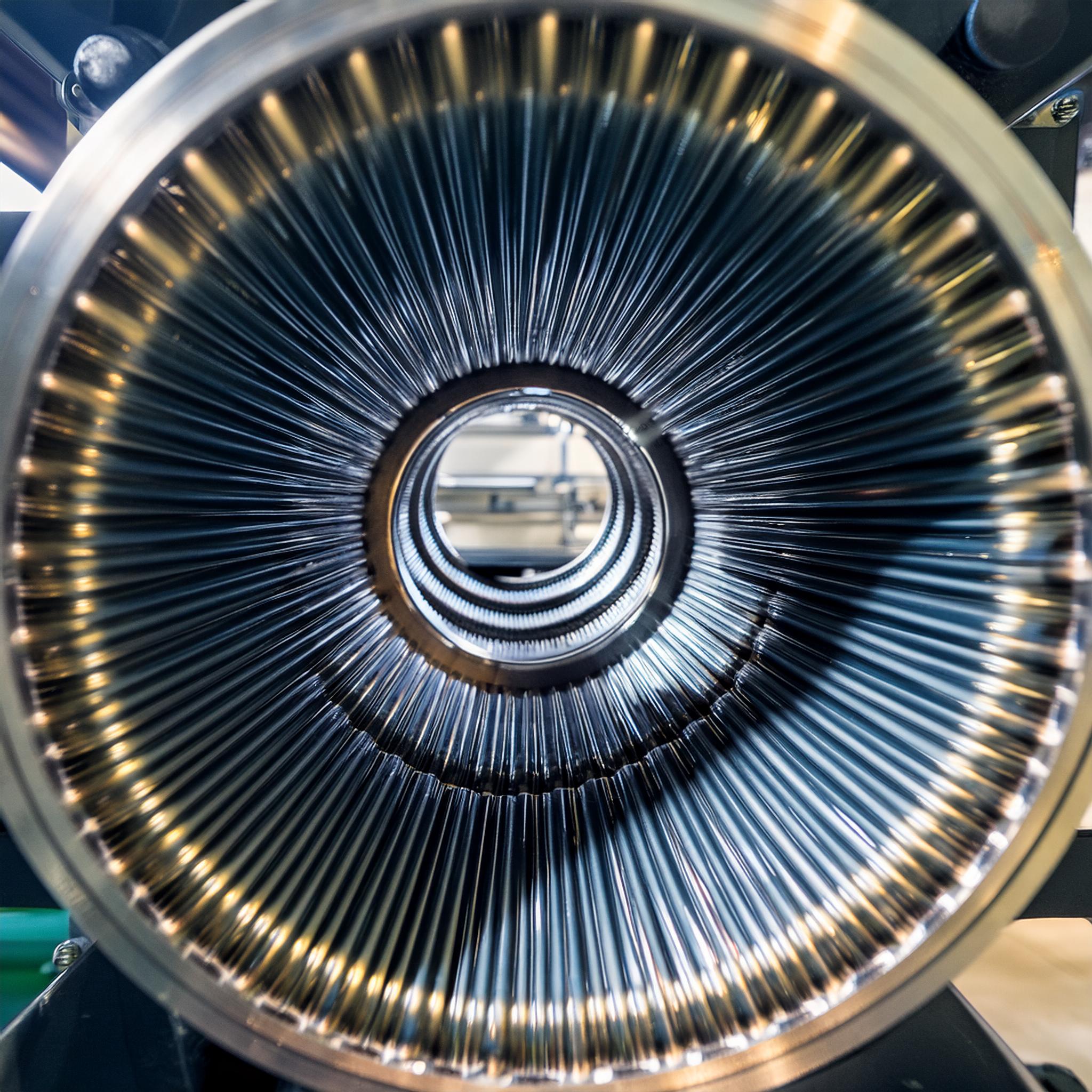

Induction Motors: Electric motors used in industry are known for their simplicity and reliability, these are widely used in industrial applications.

Synchronous Motors: Offer precise speed control and high efficiency, often used in large industrial processes.

DC Motors

Brushed DC Motors: Provide excellent speed control and are used in automotive applications and small appliances.

Brushless DC Motors: Offer higher efficiency and longer lifespan, commonly used in computer hardware and modern appliances.

Servo Motors

These provide precise control over angular position, velocity, and acceleration. They are crucial in robotics, CNC machines, and automated practices used by electric motor manufacturers.

Stepper Motors

Known for their ability to move in precise increments, these are used in 3D printers, camera systems, and other precision applications. Stepper motors excel in open-loop control systems where exact positioning is crucial without the need for feedback sensors.

Linear Motors

These produce motion in a straight line rather than rotational motion. They are used in various transportation systems and advanced manufacturing processes.

Electric Motors in Industrial Applications

Electric motors are widely applied in industries, powering a vast variety of machinery and systems. Much of their versatility, efficiency, and reliability explain their role as one of the keys to modern industrial operations. Some of the most critical industries and applications include:

Manufacturing

Electric motors and control systems drive conveyor belts, assembly lines, and various production machinery. For instance, in automotive manufacturing, robotic arms powered by servo motors perform precise welding and assembly tasks.

HVAC Systems

In commercial and industrial buildings, electric motors are essential components of heating, ventilation, and air conditioning systems. They power fans, compressors, and pumps to maintain optimal indoor environments.

Automotive Industry

Beyond manufacturing, electric motors are increasingly used in vehicle propulsion systems. Electric and hybrid vehicles rely on high-efficiency motors for primary or supplementary power.

Robotics and Automation

Precision motors, particularly servo and stepper motors, are fundamental in robotics. They enable accurate movement in industrial robots used for tasks like packaging, palletizing, and quality control inspections.

Oil and Gas

Large industrial motors power pumps and compressors in extraction, refining, and distribution processes. For example, submersible pumps in oil wells use specialized electric motor brands designed to operate in harsh environments.

Aerospace

High-performance electric motors are used in aircraft for functions such as wing flap actuation, fuel pumps, and environmental control systems.

Food and Beverage Processing

Motors power mixers, conveyors, and packaging machinery. In a brewery, for instance, motors control the precise movements required for bottling and canning operations.

Renewable Energy

In wind turbines, generators (which are essentially motors operating in reverse) convert wind energy into electrical power. Solar tracking systems also use motors to adjust panel positions for optimal sun exposure.

OUR SERVICESFrequently Asked Questions

An electric motor converts electrical energy into mechanical energy. It achieves this due to the interaction between a magnetic field and an electric current flowing in a wire winding, developing a force that revolves the motor’s shaft. This mechanism, however, might vary in different types of motors, whether AC or DC.

Electric motor testing typically involves:

- Visual inspections for mechanical damage;

- Measurement of insulation resistance by a megohmmeter;

- Checking winding resistance with an ohmmeter;

- No-load test for current draw and shaft rotation;

- Load test to evaluate the performance at rated operating conditions;

- Use proper safety precautions;

- Сonsult your motor’s manual for specific testing instructions.

Motor efficiency is calculated using the formula: Efficiency (%) = (Output Power / Input Power) x 100. Output power is typically measured in mechanical watts while the input is measured in electrical watts. Accurate measurement normally requires dedicated equipment and should be carried out by a qualified technician.

AC Motors include:

- Induction motors;

- Synchronous motors;

- Universal motors.

DC Motors include:

- Brushed DC motors (Series, Shunt, Compound);

- Brushless DC motors;

- Permanent magnet DC motors;

- Servo motors.

That depends on:

- The application;

- Power output required;

- Operating environment;

- Control precision required;

- Energy efficiency required;

- Budget.

To be very precise in selection, consult an electrical engineer or motor specialist who examines your needs and prescribes the best motor type.